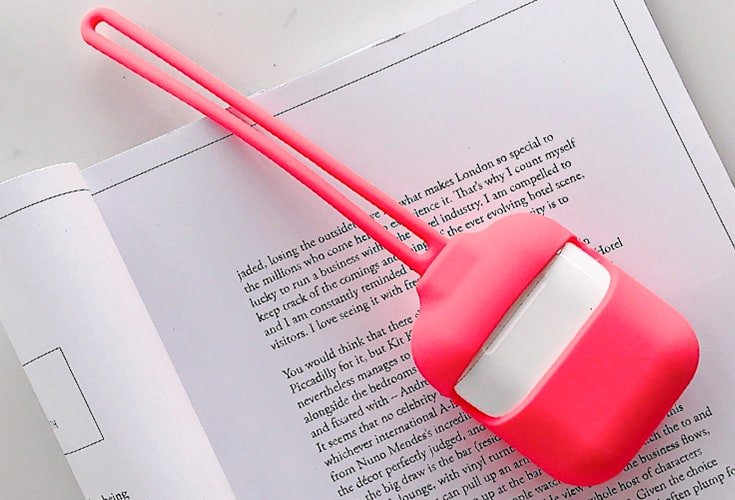

Thanks to the rise of mobile electronic products, FITMOLD provides customers with silicone protective covers for smart phones, tablets pads, smart headphones, music players and other products according to market demands. At the same time, our company also provides customers with rubber products development and mold production, and provides various kinds of rubber sealing rings, rubber protective bushings, rubber waterproof and rubber dustproof parts, and various rubber protective products.

FITMOLD can apply rubber material such as: Natural Rubber, Nitrile Rubber Butyl, SBR, Colored EPDM, Neoprene, Silicone, Viton™, Fiber Molding Compounds in our rubber molding and custom rubber molded part manufacturing; We work to produce the highest quality in custom rubber-molded products while providing each customer with the necessary attention to ensure their needs are met. If you are in need of assistance with product development and manufacturing, do not hesitate to contact FITMOLD for Rubber Molding quote. We are experts in a variety of molding services including, rubber injection molding, compression molding, transfer molding, and rubber-to-metal bonding.

Liquid Rubber injection molding

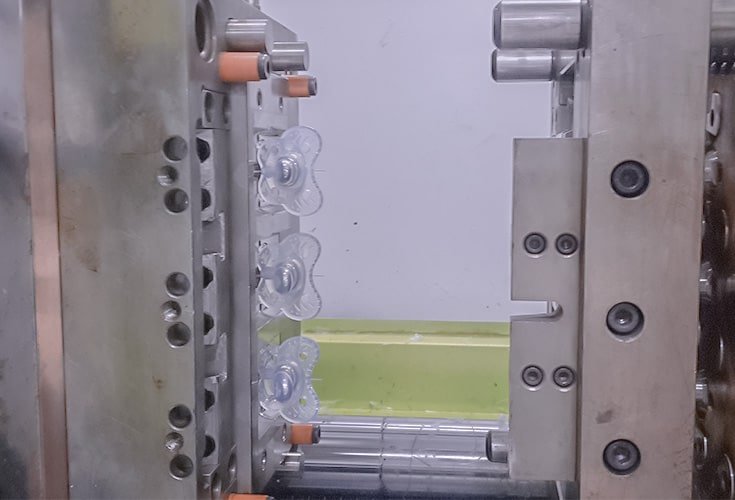

Liquid Injection Molding (LIM) or (LSR) Injection is the process where a two part liquid silicone compound (A & B parts) are delivered at a fixed ratio into a static mixer. The LSR mixture blends with a platinum cure system and is delivered into the injection unit where it is injected through a runner and gate system into the closed mold until cured. At the end of the cycle the parts are removed or ejected from the cavities and the next cycle begins. Benefits of LIM molding includes:

- Automated closed-loop systems limit contamination

- Nearly “flash-less” parts

- Optimized cycle times

- Liquid Rubber injection molding is well suited to the unique needs of the medical product industry

- Liquid Rubber injection molding materials are biocompatible, inert and stable, flexible, have a low compression set with awide range of Durometers, and offer superior heat resistance.

- High quality components with complex shapes can be repeated in high quantities in a costeffective manner.

Liquid Rubber injection molding is good for high-tolerance, precision rubber molded products, smooth surface products with light parting line mark, Sterile products such as maternal and baby products, personal care, medical equipment, etc.

Rubber Compression Molding

Compression Molding is the original production method for molding rubber. It is ideal for low to medium production volumes and is a particularly useful molding process for molding gaskets, seals, O-rings, boots, and large, bulky parts. It is a widely used, efficient and economical production method for many products, particularly low production volumes of medium to large parts and higher cost materials.

Processes:

Compression molding involves taking rubber compound or mixed raw material and making “pre-forms” that are close to the shape of the finished product. These shapes are then loaded, typically by hand, into an open mold. The mold is closed, the rubber cured, and then de-molded.

Compression molding can be cost effective if one or more of the following is true:

- Compression molding tooling already exists

- The quantity required is low

- The cross-section of the part is very large and requires a long cure time

- It has a Rubber to Metal Bonding application

- Extreme material hardness is required

- Larger Parts required – Our Molding Platen sizes range from 12” x 12” to 45” x 45”

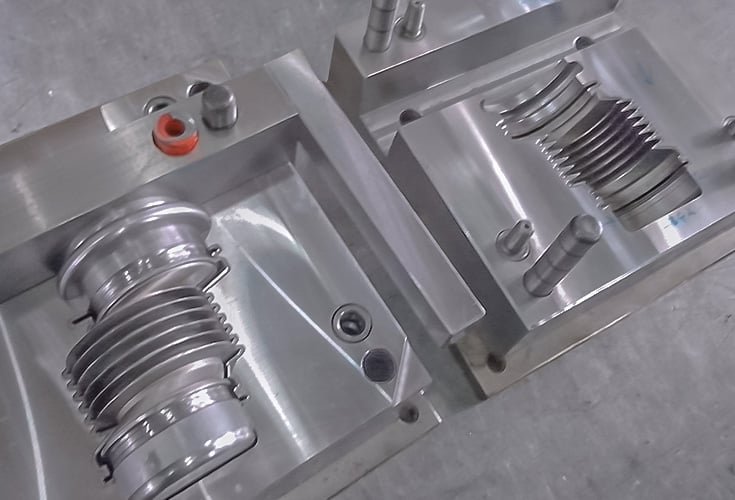

Rubber Transfer Molding

Transfer Molding combines the advantages of injection molding with the ease of compression molding. Rubber transfer molding is an ideal process for molding parts that require multiple cavities, intricate parts that require a closed mold, bonding rubber to metal parts and if the geometry of the part might cause mold cavities to trap air.

Processes:

Like compression molding, transfer molding requires secondary raw material preparation into “pre-forms” that are loaded into a “pot.” When the mold is closed, a “piston” compresses the rubber in the “pot” and forces it through holes or sprues into the cavity to fill the part cavity.

The advantages of transfer molding over compression molding can include:

- Fewer and simpler pre-forms because one pre-form canfill many of cavities.

- Tighter dimensional tolerance control because the moldis closed, therefore it is not held open by excess material spilling out of the cavity parting line during molding. This keeps part geometry more exact and parting lines smaller and less noticeable.

- Colored rubber parts benefit because pre-forms can be cut by hand from raw material sheets,significantly reducing the chance of contamination that can come from mechanical prep for compression molding or the injection screw and barrel in injection molding.

- Material in the “pot” pre-heats before being forced into the cavities. This decreases the viscosityof the material, allowing it to flow more easily into the cavities for reduced cure time. The primary disadvantage is increased waste; the “flash pad” or rubber left in the pot after transfer is typically cured and has to be discarded.

Liquid Rubber injection molding

Rubber Compression Molding

Rubber Transfer Molding

Rubber Parts Making

Related Products