When you work with FITMOLD – from concept design through to product launch – you can depend on the highest level of quality from all of our sites, validated by national, regional and international standards. These cover products and processes, as well as providing clean, safe, healthy environments for all our colleagues.

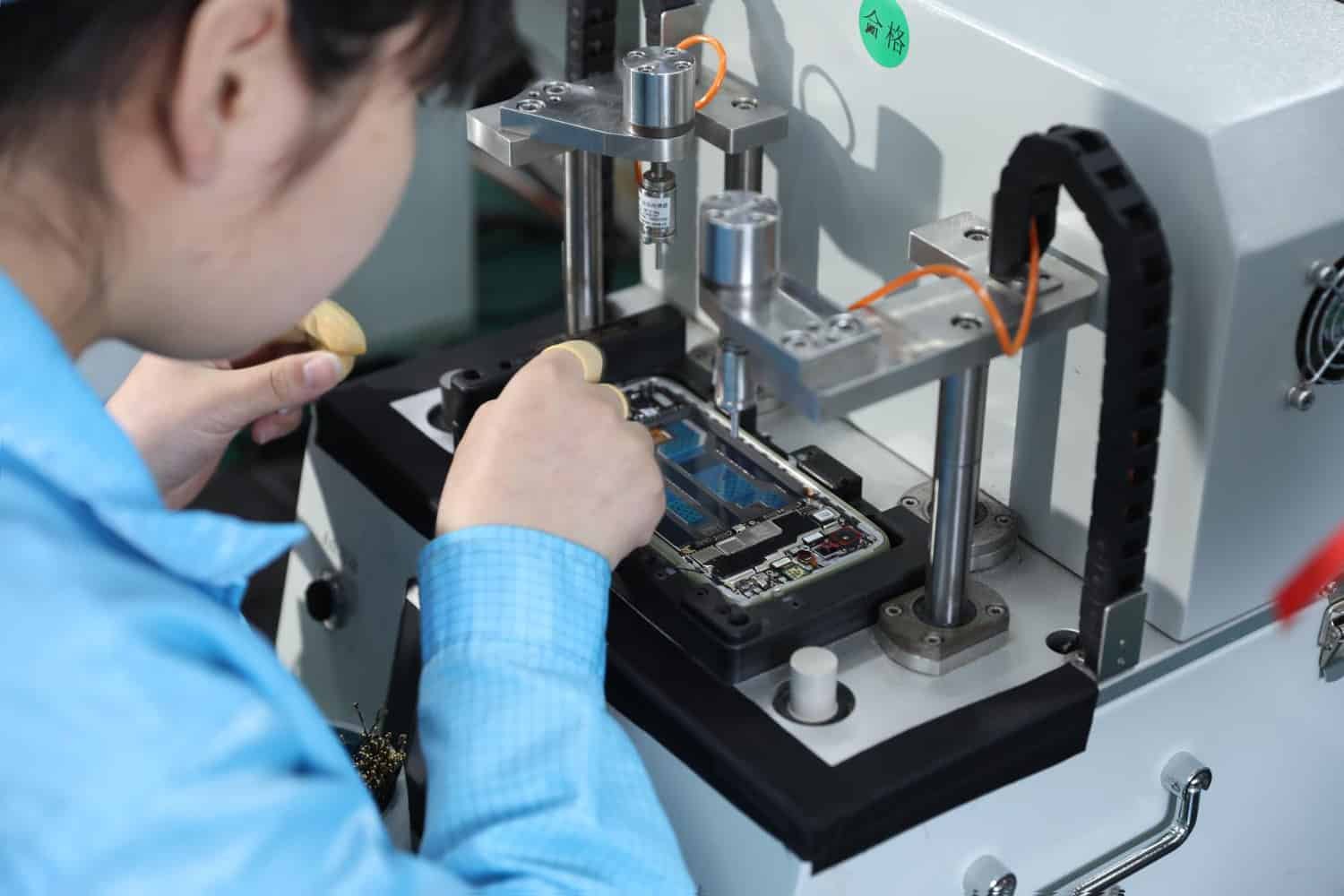

Quality Assurance

To consistently exceed customer expectations, quality control and assurance is achieved through:

● Comprehensive written procedures and policies

● Extensive electronic records of orders, customer communications and inspection results

● Detailed records of incoming raw materials

● Analysis of root cause of non-conformances

● Corrective actions to prevent recurrence of non-conformances

● Multi-level incoming order review

● Comprehensive software expert system advising customers of manufacturability issues

● Periodic calibration and labeling of inspection tools

● Designated areas for non-conforming parts

● Staff members being strongly encouraged to suggest improvements in methods, materials, and suppliers

● Daily backup of electronic records stored in multiple locations

Material testing

Size detection

Appearance assessment

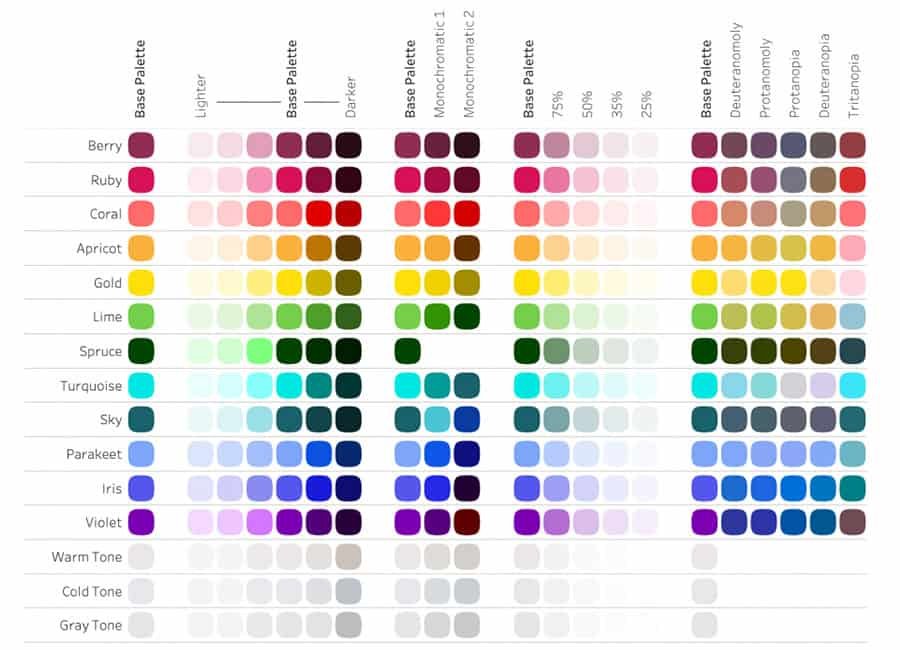

Color detection

Advanced Inspection Equipment In-House

Visual Quality Standards

At Fitmold, we have implemented a Visual Quality Standard for our finishing services to inspect painted finishes and ensure the consistency of cosmetic appearance. We also have a Visual Quality Standard for our plastic injection molding services. This ensures we have a consistent method for inspecting parts. Ensure the surface consistency of different batches of parts.

XRF Analyzer

X-Ray Fluorescence (XRF) analysis is a non-destructive testing (NDT) process by which materials such as metals, plastics, ceramics, etc. are exposed to low level, short-wave X-rays or gamma radiation. Each element reflects the emission with a different wavelength and a specially calibrated spectrometer can analyze the wavelengths to detect what elements are present and in what relative concentrations. The XRF analyzer can also detect banned materials under the REACH and RoHS legislation.

Two-dimensional measuring instrument

Mainly used in calipers and angle rulers that are difficult to measure or cannot be measured at all, but play important parts and angles in assembly. It is widely used in machinery, electronics, molds, injection molding, hardware, rubber, and low-voltage electrical appliances. , Magnetic materials, precision hardware, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, computers (computers), liquid crystal televisions (LCD), printed circuit boards (circuit boards, PCB), automobiles, medical equipment, watches, Instrumentation, screws, springs, gears, cams, threads, radius templates, thread templates, wires and cables, tools, bearings, stamping parts, screens, test screens, cement screens, mesh panels (steel mesh, SMT template), etc.

Coordinate Measuring Machine

At its most basic a coordinate is a point, a fixed singular location in three-dimensional space. A series of points can be used to define the parameters of a complex shape. Therefore a coordinate measuring machine (CMM) is any device that is able to collect this set of points for a given object and to do so with an acceptable degree of accuracy and repeatability.

ISO Certified

We are proud to be fully certified. This demonstrates our commitment to continuous quality improvement, respect for our workers and for the environment.