Customizing Car Dashboard Covers With Injection Mold

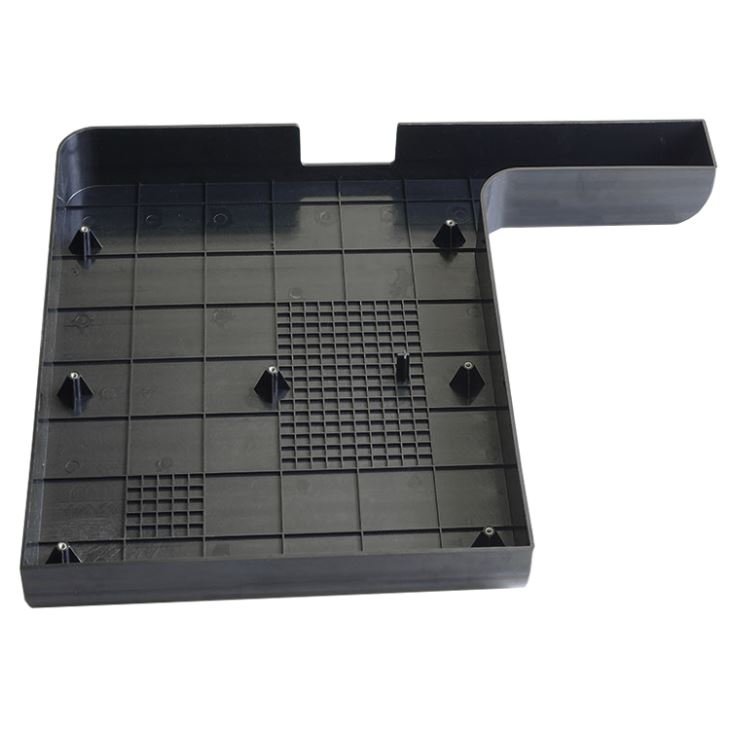

Urine Analyzer

Plastic injection molding for Urine Analyzer

Part Material: ABS

Surface Treatment: Polish

Production Process: Plastic injection molding

Our company is specialized in plastic injection mold making and plastic injection molding manufacturing, applied for medical equipments such as chemistry analyzer, clinical analyzer, urine cytometry and son on.

| Plastic Injection Mold/Mould And mass production process | Description |

| 1. 3D/2D Design/Samples for quotation | According to 3D/2D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold (moulds) | Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold progress (picture). |

| 6. Sample shoot | We provide the moulds test samples for confirmation(about 5-15 piece), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your requirement. |

| 8. Delivery | deliver goods by air or by sea. |

FAQ

Q1: What kind of steel do you use for injection plastic molds?

A1: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q2: Can you provide the steel certificate and heat-treatment certificate?

A2: Yes, We can provide steel certificate or hardness certificate to prove.

Q3: Can you make oil painting/ silk screen printing/ powder coating etc for those plastic injection molded parts?

A3: Yes, As plastic mold factory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.