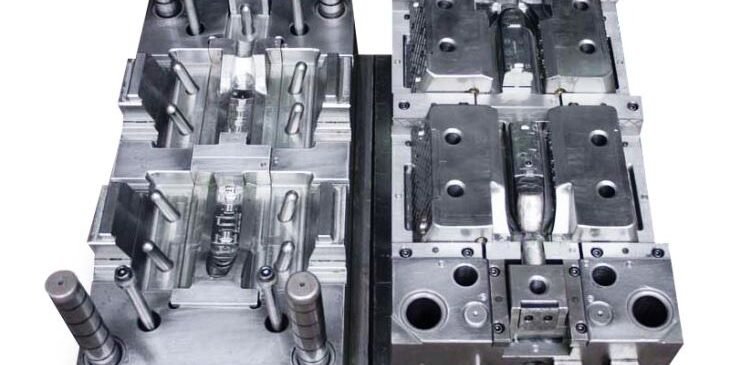

Plastic Injection Tooling With Plastic Injection Molding Service

| Mould Name | Plastic Injection Tooling with Plastic Injection Molding Service |

| Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%…etc. |

| Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc…Metal…etc. |

| Quality: | ROSH and SGS standard |

| Size: | According to your drawing |

| Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

| Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

| Mould Base: | HASCO standard, European standard, World standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finish: | Texture (MT standard), high gloss polishing |

| Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

| Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

| Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

| Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

| Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

FAQ

1. Q: How do you pack the china plastic moulds? How about the plastic injection mold packaging?

A: We pack the plastic moulds in wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement.

2. Q: Do you make spare parts for your customer?

A: Yes, we will provide spare parts for the mold if needed or required by client.

3. Q: what is the minimum & maximum unit weight and size your machines can produce?

A: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

4. Q: What kind of molds do you make? Plastic injection mold, Compression mold or something else?

A: We are mainly making plastic mold injection and rubber compression mold.We also make die casting molds and metal stamping molds according to our customer’s requirements.