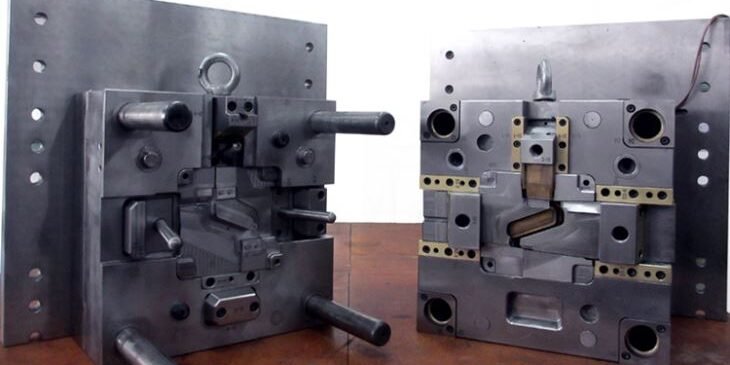

Plastic Injection Tool

| Product Name: | Plastic Injection Tool |

| Material: | Aluminum :ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100, etc Zinc alloy: Zmark3,Zmark5,ZDC3, etc Brass: HPb59-1,HPb62-1, etc |

| Drawing format: | CAD / PDF/ DWG/ IGS/ STEP/ X_T/ SAT /STL |

| Process: | Drawing & Samples → Mould making → Die casting → Deburring→ Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing → Shipping |

| Surface treatment: | Polishing, Sandblasting, Painting, Powder coating ,Galvanizing, Chrome plating |

| Production capacity: | depend on complicacy of different products and the quantity |

| Lead time : | making arrangement upon customers request |

| Term of Payment: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal |

| Testing facility: | Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester. |

FAQ

1. Q: Do you build hot runner plastic moulds?

A: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as

DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc.

The manifold recommended for your tool is selected to meet your individual needs.

2. Q: What kind of steel do you use for plastic mouldings?

A: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

3. Q: Can you make the texture / text / heat-treatment /nitriding for the inejction mold plastic?

A: Yes, As plastic mold fatory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

4. Q: How long is the lead-time for a plastic injection mold?

A: It all depends on the mold’s size and complexity.Normally, the lead time is 25—45days.

If the Plastic Moulds are very simple and in small size, we can work out within 15 days.