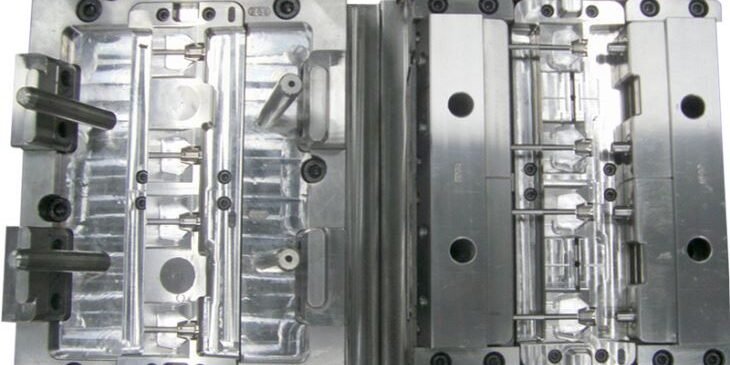

Plastic Injection Molding Tool Building Mold Design Analysis

| Product Name | Plastic Injection Molding – Tool Building – Mold Design & Analysis |

| mould material | 45#,P20,H13,718,2738,NAK80,S136. |

| mould base | LKM,HASCO |

| Cavity | 1 or more |

| Runner | cold or hot runner |

| Mould life | 45# :300,000-500,000shots |

| P20: 500,000shots | |

| 718: 700,000shots | |

| Design software | UG,PROE,CADetc. |

| Plastic material | PP,PE,ABS,PC PET pa66 . |

| Delivery time | 30 days |

| Specification | with good quality lower price |

FAQ

1. Q: How long is the lead-time for a plastic injection mold?

A: It all depends on the mold’s size and complexity.Normally, the lead time is 25—45days.

If the Plastic Moulds are very simple and in small size, we can work out within 15 days.

2. Q: Do you make spare parts for your customer?

A: Yes, we will provide spare parts for the mold if needed or required by client.

3. Q: what is the minimum & maximum unit weight and size your machines can produce?

A: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

4. Q: What kind of plastic materials you usually use?

A: We are specialized in producing plastic products with the following materials:

PP,ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.