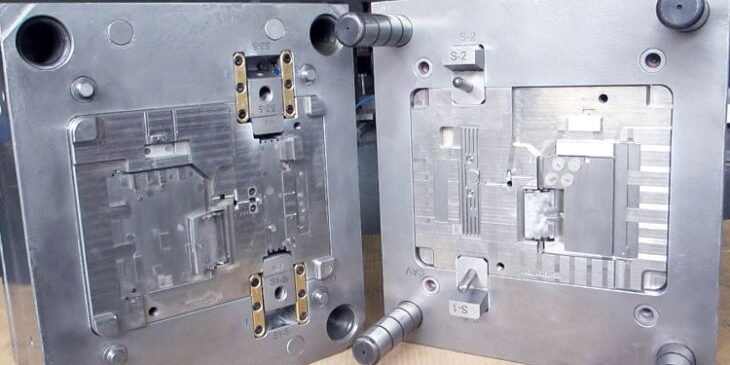

Industrial Injection Mold

| Product Name | Industrial Injection Mold |

| Mould material | P20 steel, 718, 2738,H13, NAK80,2344,2343,S136,etc…. |

| Fast mould design | can be within 1-3 working days after getting customer’s drawings |

| Lead time | 3- 6 weeks after getting the mould design confirmation |

| Mould testing | All of the moulds can be well tested before the shipments. Videos for testing the moulds are available. |

| Minimum order: | small orders can be accepted |

| Runner | Hot/cold |

| Payment terms | L/C T/T Western Union Money Gram |

| Mould making service | OEM/ODM service available |

| After sales service | Available by our staff with more than 10 years of working experience in this field |

FAQ

1. Q: What kind of molds do you make? Plastic injection mold, Compression mold or something else?

A: We are mainly making plastic mold injection and rubber compression mold.We also make die casting molds and metal stamping molds according to our customer’s requirements.

2. Q: What types of files do you accept (drawings)?

A: With our CAD systems we can accept following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

3. Q: What kind of steel do you use for plastic mouldings?

A: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

4. Q: Can you make the texture / text / heat-treatment /nitriding for the inejction mold plastic?

A: Yes, As plastic mold fatory, we have long-term cooperated subsidiary factories that do those processes.