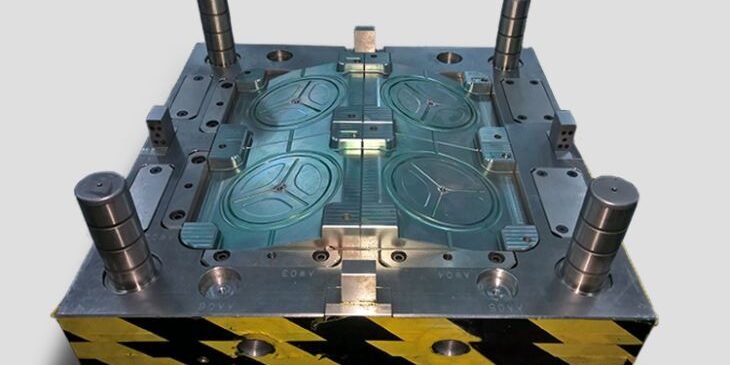

Export Plastic Injection Molding Tool

| Company | Fit Precision Mold Co., Ltd |

| Business Type | Manufacture |

| Products Name | Auto Plastic Injection Mould for NISSAN Rearview Mirror |

| Place of Origin | Shenzhen,China |

| Quality System | ISO9001 |

| Mould life | 300,000-500,000shots |

| Mould base Material | Standard LKM,HASCO,customized |

| Core&Cavity Material | Nak80,P20,H718,S136,SKD61,2738,DC53,H13…. |

| Products Material | ABS,PP,PVC,PET,PA66,PA6, |

| Design Software | UG,Pro E Solidwork, AutoCAD, Moldflow…. |

| Runner | Hot runner,cold runner |

| Gate | Side gate,Sub gate,Pin point Gate… |

| Delivery Time | 25-30days for mold,plastic products according to quantity |

| Package | Wooden box for mould,carton for plastic products |

| Experience | 15 years experience in plastic injection mold making and plastic products produce |

FAQ

Q1: How many injection plastic mouldings machines do you have?

A1: We have 20 sets of plastic Injection Mouldings machines.

Q2: what is the minimum & maximum unit weight and size your machines can produce?

A2: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the following materials:

PP,ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q4: How do you pack the plastic molded parts?

A4: We pack the plastic molded parts by thick-wall export cartons.

If the finish surface of plastic molded parts requires safe protection to avoid scratches, we will use bubble plastic bag to pack the parts.