Customized Skoda Cup Holder With Injection Molding

FIT PRECISION MOLD CO., LTD specializes in providing good design and high-precision products at product developing and producing area. Our professional staff are experienced at tool/mold making service including plastic injection mold (mould),die casting mold (mould) and metal stamping mold (die); At the same time we are involved in molded part producing such as plastic parts, castings parts, plastic & metal extrusion parts, stamping parts, rubber parts, and precision machined parts;

Our broad range of products covers from building hardware & materials, household appliances, electronic components, auto and motorcycle parts, to accessories in telecommunication parts as well as the process after production and surface treatments. We also provides customers with specialized technical advice and review, in order to achieve good quality of the request.

Specification:

Name:Automotive Cup Holder for Skoda

Mould Material:Steel 718H, P20,NAK80, 1.2344,etc

Mould Life:300,000~1,000,000 shots

Mould Analysis:Supply Mould analysis in detail (pins, gate, plate, slider etc.)

Cavity:Single, Multi (1*1, 1*2, 1*4, 1+1, 1+1+1, etc.)

Mould Runner:Cold runner, Hot runner

Applied Software:Pro/E, UG, Auto-Cad, Solid work, CAM

Surface Treatment:Logo printing, Texture, Polishing, Painting, Powder Coating etc.

Product Material:Nylon GF, ABS, PP, TPU/TPR, PVC, PPS, POM, PC, PE, HDPE Etc.

Processing Trade Form:OEM&ODM

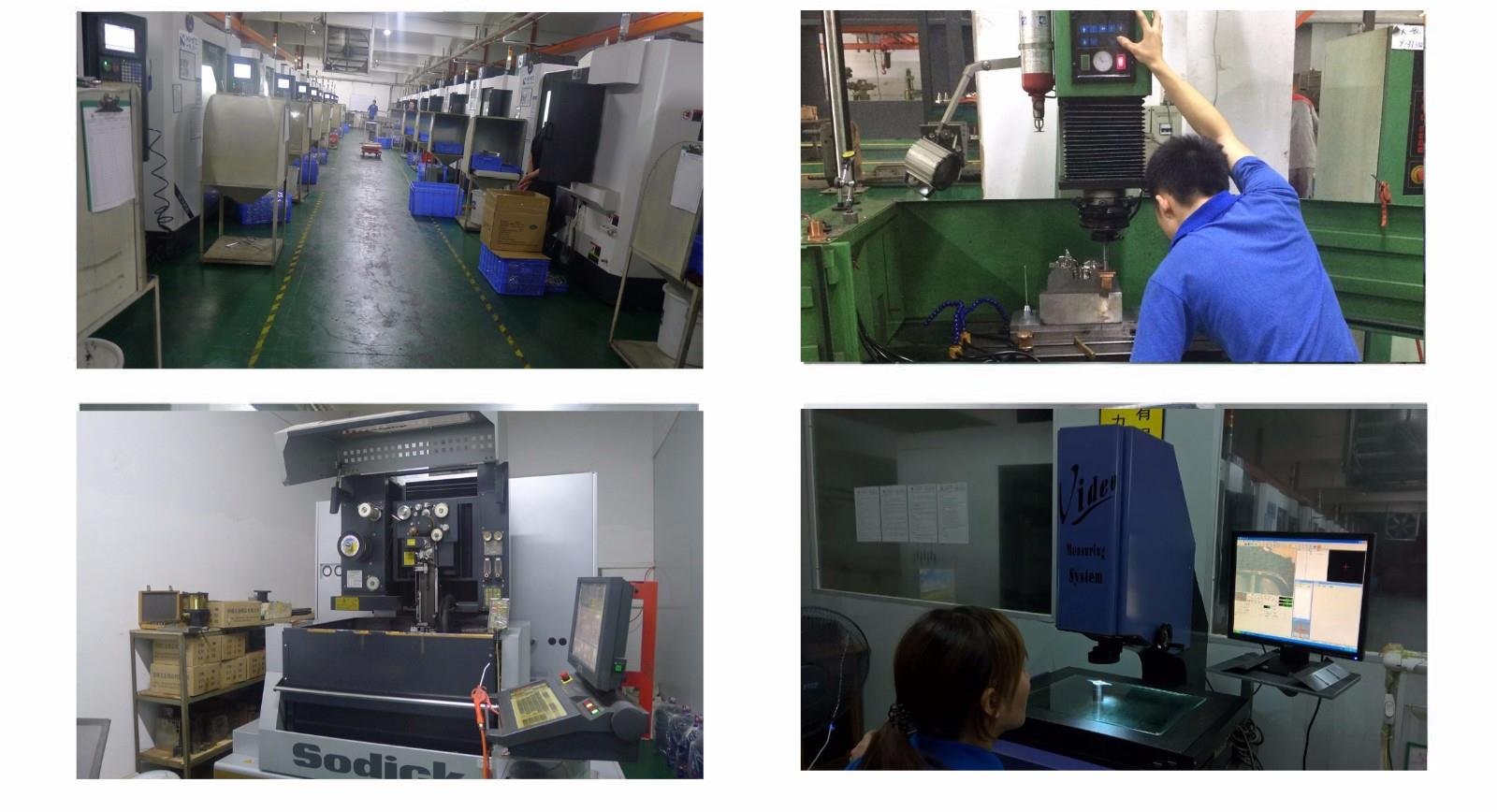

Main Processing Equipment:LKM, DME, HASCO

Injection Molding Machine:80 MT – 1600 MT

What is your advantage?

1. Has sound and mature supporting supply chain

2. High efficiency of development and design ability and short process time.

3. Cost effective and good service attitude.

4. More professional export sales staff who are all know rubber processing very well.

FAQ

1.Q.What do you do if your product has a quality problem?

A:First of all, our products are strictly controlled through a series of layers, customers will conduct photo inspection, and finally shipped packaging, so quality problems rarely appear.

Secondly, if there is an unforeseen accident, we will deal with it in time and never shirk responsibility.

We are looking for long-term cooperation rather than temporary partners.

2.Q.How do you pack the plastic molded parts?

A.We pack the plastic molded parts by thick-wall export cartons.

If the finish surface of plastic molded parts requires safe protection to avoid scratches, we will use bubble plastic bag to pack the parts.

Production equipment

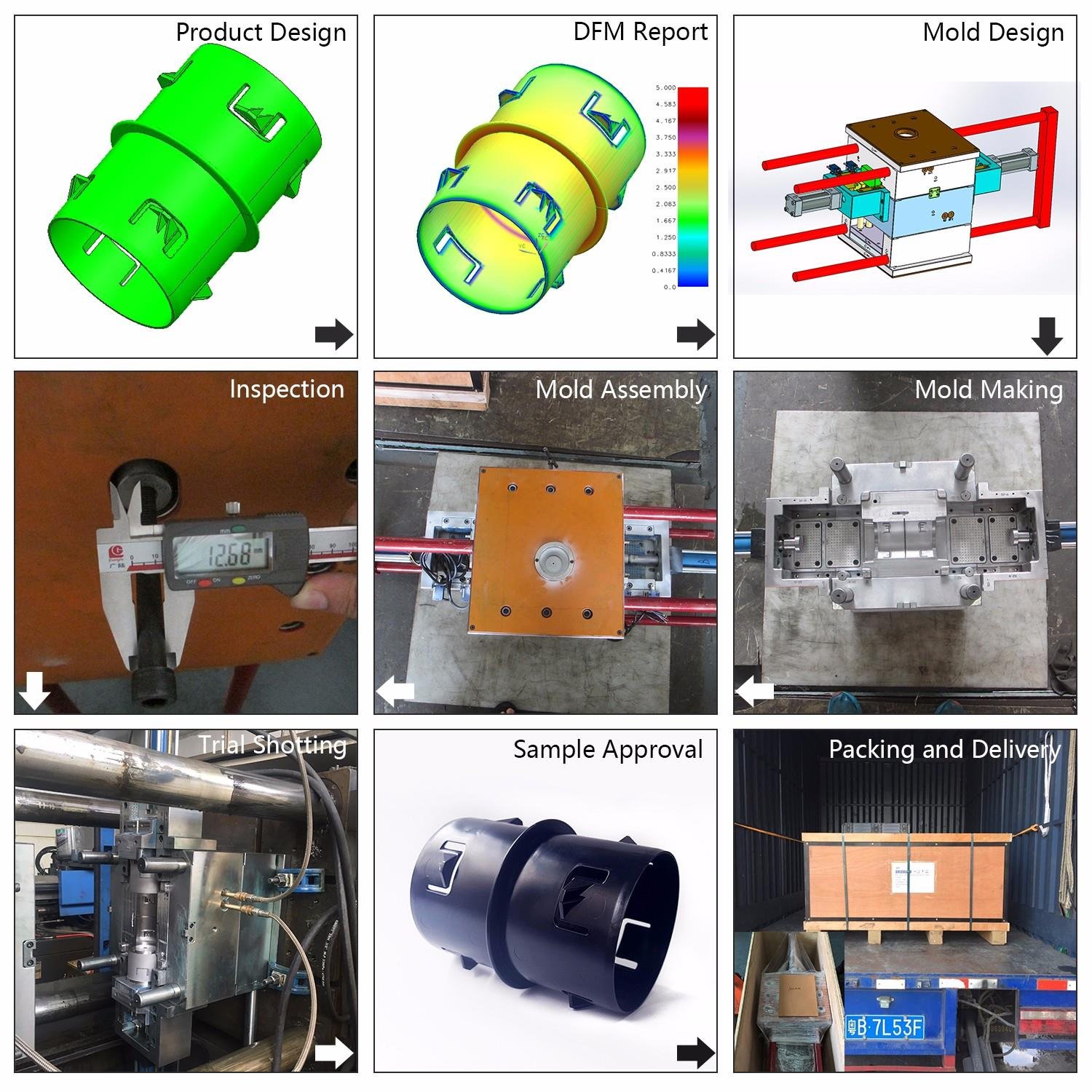

Fitmold Mold Delivery FLow Chart