Custom PVC Plastic Car Mudguard Fender Auto Accessories

FIT PRECISION MOLD CO., LTD specializes in providing good design and high-precision products at product developing and producing area. Our professional staff are experienced at tool/mold making service including plastic injection mold (mould),die casting mold (mould) and metal stamping mold (die); At the same time we are involved in molded part producing such as plastic parts, castings parts, plastic & metal extrusion parts, stamping parts, rubber parts, and precision machined parts;

Our broad range of products covers from building hardware & materials, household appliances, electronic components, auto and motorcycle parts, to accessories in telecommunication parts as well as the process after production and surface treatments. We also provides customers with specialized technical advice and review, in order to achieve good quality of the request.

Specification:

Product Name:PVC Mudguard Car Fender

Part Material to Choose: ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc.

Customized: We accept customized product.You can provide us the product or 3D drawing.

Tolerance: ± 0.02mm

Software: CAD, Pro-E, UG, solid works, etc.

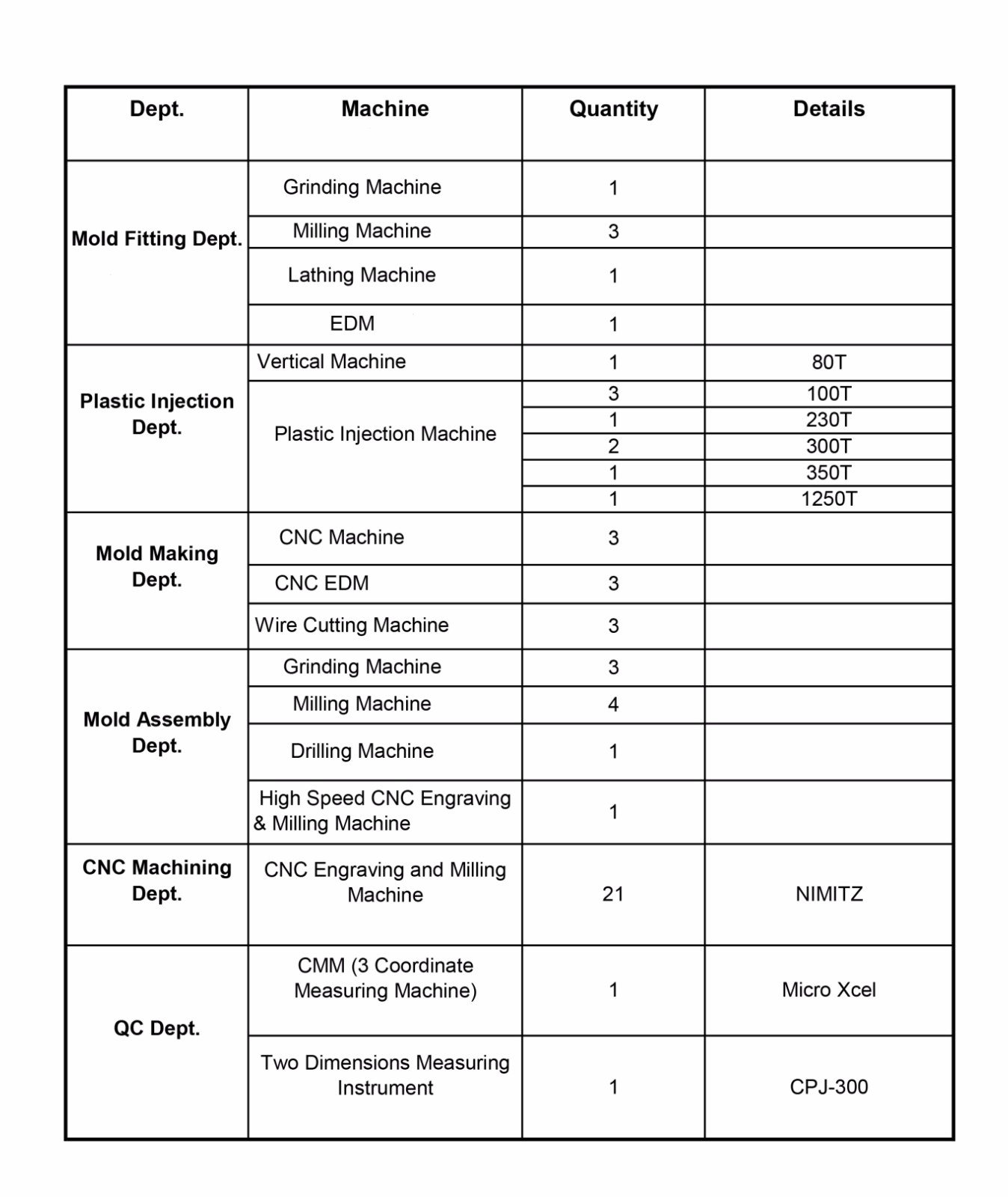

Equipment: Injection moulding Machine, CNC Center, Grinding Machine, EDM, WEDM…

Quality Control: Following the quality systems ISO9001, Fitmold takes quality controls step by step, from design audit, incoming material checking, inspection at each process, to FAI inspection, final verification of molds & parts.

Design Time: 2-5 days, it depends on product complexity

Payment term 50% deposit, 50% before delivery

Application: Apply for automotive industry, electronic and electrical appliances, medical industry, fiber-optical and transmission industry and customized components, concerning connector molding parts, auto parts, medical parts and other tooling, etc.

What is your advantage?

1. Has sound and mature supporting supply chain

2. High efficiency of development and design ability and short process time.

3. Cost effective and good service attitude.

4. More professional export sales staff who are all know rubber processing very well.

FAQ

Q1: What kind of molds do you make? Plastic injection mold, Compression mold or something else?

A1: We are mainly making plastic mold injection and rubber compression mold.We also make die casting molds and metal stamping molds according to our customer’s requirements.

Q2: What kind of steel do you use for plastic injection moulds?

A2: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Equipment List

Production equipment