Sea Shipment For Light Controller Cases

3000sets Light Controller Cases are picked up by shipping company today and arrange the sea shipment soon.

This is custom heading elementDescriptionFeedbackDescription Toy Doll 3D Printing 3D printing rapid prototype is a process of making a three-dimensional solid object of virtually any shape from a digital model. It is achieved using an additive process, where successive layers of material are laid down in different shape. Material available Plastic(ABS, PP, POM, PC, PC+GF,…

This is custom heading elementDescriptionFeedbackDescription Part Name Rubber Dampers | Shock Absorbers | Vibration Reduction Service OEM OR ODM Part Material Silicone or rubber (NR, NBR,SBR,BR,IR,CR,EPDM,IIR, VITON(FKM),SIR,PU,ACM,CO,etc) Material Hardness Silicone about 20~80 Shore A; rubber about 30~90 Shore A Color Customized according to Pantone colors Appearance as customer’s requirement Drawings 2D or 3D acceptable Temperature Resistance -40~300 degree centigrade Tolerance 0.05mm Technology Hot pressing molding or injection molding Second Processing Vulcanizing / Deburring / Silk-screen / Carving / printing Part Feature 1.Oxidation , Chemical,oil, acid ,alkali , weather resistance 2. colorful ,Anti-aging,good flexibility, good elasticity Food grade material FDA or LFGB Shipping ways 1. By sea. 2. By express: DHL/UPS/FEDEX ,etc 3. By air Package Normally PE bag+carton or customized as customer’s request Trade Term Ex-works; FOB Shenzhen ; CIF Payment Term Sample mold: 100% prepaid,MP Mould: 50% deposit by T/T in advance, balance 50% paid after samples approval Goods: 50% deposit, 50% before shipment T/T, Western Union, PAYPAL Lead time 5~10 days for making mold,7~15 days for mass production (depends on part structure ) Specification…

This is custom heading elementDescriptionFeedbackDescription Airbag cover injection molding Airbags have to be protected from damage to ensure their reliable deployment throughout the vehicle’s life cycle. The airbag protection solution should take up as little assembly space as possible and enable cost-effective production and assembly. Fit Precision Mold Co., Ltd 1 Company’s strength…

This is custom heading elementDescriptionFeedbackDescription Monitor Rapid Prototype CNC machining monitor prototype Materials: ABS PC Process: CNC milling, polish, heating insert, coating, printing Tolerance: +/-0.05 – +/- 0.1mm Surface roughness: high polish and printing, Ni-coating Surface treatment: anodizing, hard anodizing, plating, polishing, heat treatment File format: 3D: IGS, PRT, STEP, STP, SLD 2D: DWG. CDR. PDF.…

This is custom heading elementDescriptionFeedbackDescription Hematology Analyzer Product Specification: Part Material: ABS Surface Treatment: Polish, silk screen printing, oil painting Production Process: Plastic injection molding Our company is specialized in plastic injection mold making and plastic injection molding manufacturing, applied for medical equipments such as biochemistry analyzer, biochemistry analyzer, clinical chemistry analyzer and son on.…

This is custom heading elementDescriptionFeedbackDescription Die Cast Motorcycle Wheel Hub Specifications: Item: Casting Hubs for Honda motorcycle Part material: Aluminum Surface finish: Powder Coating Color: Silver Tolerance: 0.01-0.05mm Inspection report and material test certifications are available upon requests Note: Customize size or pattern is available. Package: PP bag and Carton Box General Service range:…

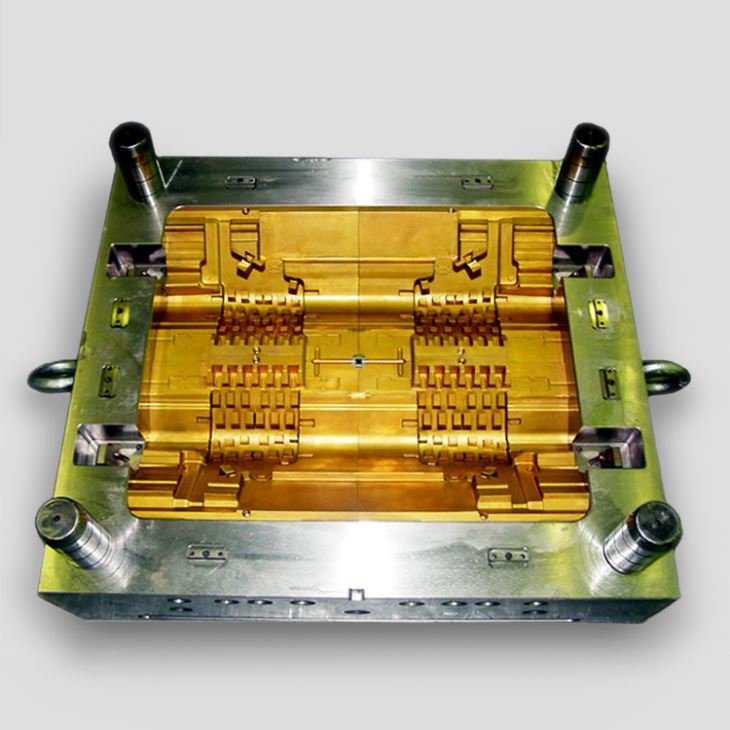

This is custom heading elementDescriptionFeedbackDescription Product description Advantages: 1. Competitive price 2. Strict quality control system 3. Quick mold making and delivery 4. Advanced equipment, excellent R&D teams 5. Professional technicians and rich experienced workers Item Description 1.Mould material P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 2.Hardness of steel vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 3.Inserts / Slider steel…