Lastest Trends In Plastics Processing

One of the trade show highlights is the Omniplast competition. It has become a permanent fixture on the Plastpol agenda. Organised by Targi Kielce, the event targets all companies and company representatives exhibiting at the 22nd International Fair of Plastics and Rubber Processing. The competition aims to disseminate and popularise the knowledge of plastic processing and related processing technologies. After several competition stages have already taken place, Plastpol will see the grand finals held at Targi Kielce on 22 May 2018 at the fair.

This is custom heading elementDescriptionFeedbackDescription Specifications: 1. Materials Available: Stainless Steel: SS201, SS303, SS304, SS316 etc. Carbon Steel: AISI 1045, 9SMnPb28 etc Brass:C36000 (C26800), C37700 (HPb59), C38500(HPb58), C27200(CuZn37), C28000(CuZn40) , etc. Bronze: C51000, C52100, C54400, etc. Iron: grey iron and ductile iron Aluminum: 6061, 6063,7075,5052 etc. 2. Processing Method: Machining, turning, milling, drilling, grinding,…

This is custom heading elementDescriptionFeedbackDescription Metal Stamping Housing Product description: metal stamping housing Assembling way: welding and polish 1. Item: auto parts, medical, telecom, automotive, mobile, computer, electronics, furniture hardware, and mechanical equipment, printers, forging parts, stamping parts. 2: Material available: steel, stainless steel, carbon steel, aluminum 3. Surface treatment: e-coating, zinc-plated, chrome-plated, powder coating…

This is custom heading elementDescriptionFeedbackDescription Auto Battery Terminal Cover Over 10 years’plastic injection molding manufacturing experience, exporting to over 30 countries worldwide. Own ISO 9001:2008 certified factory with strict QC inspection system. OEM/ODM services & Customization service available. Production process and quality control process are approved by ISO 9001:2008 Inspection report and material test certifications…

This is custom heading elementDescriptionFeedbackDescription MODEL: Printer Accessories Plastic Injection Mold Tolerances Optional: a) Fractions ±1/16 b) Decimals X.XX ±0.01 c) Angles X.X ±0.1 Material Optional: a) mold base: S50C steel or P20 b) Mold Cavity steel: 738,718H,8407,NAK80,S136,etc. c) Mold Core steel: P20,H13,718,2738,NAK80,S136,etc. d) Mold components: LKM,DME or HASCO standard. Surface finishing: a) Texture or Matt finish b) Gloss…

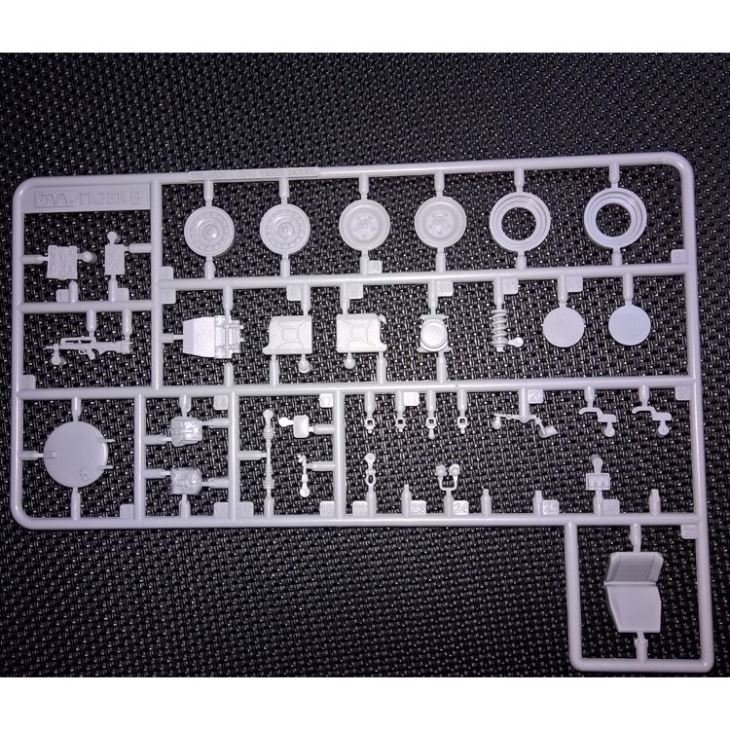

This is custom heading elementDescriptionFeedbackDescription Model Car Kits From an engineering point of view, a particular car model is usually defined and/or constrained by the use of a particular car chassis bodywork combination or the same monocoque, although sometimes this is not the case, and the model represents a marketing segment. Fit Precision Mold Co.,…

This is custom heading elementDescriptionFeedbackDescription Auto Part Injection Mold Mold Shaping China Customized Plastic Injection mold De-mold Type Automatic Eject Mold Base LKM & Hasco & DME or other Mold Material NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#45#etc Mould Cavity Singe or multi as your requirement Sprue Gate YUDO runner, Hot…

This is custom heading elementDescriptionFeedbackDescription Mould material plastic Cavity 1 cavity/2 cavity / multi cavity Runner hot runner /cold runner Mould life 300,000-500,000 shots Processing method forings, CNC milling and turning, grinding, casting, broaching, etc Design softwares NX-UG, Pro/E, Moldflow, Auto CAD Hardness of steel 46~56HRC A surface request EDM&High polish Payment terms T/T, L/C, Paypal…

This is custom heading elementDescriptionFeedbackDescription Product Name Injection Tool for Wireless Sensor Case Cover Mould material P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2767, H13,8407, 420SS, S136, S-7 Information to quote 2D,3D,samples or pictures of multiple points of view with dimensions. Leadtime for mould Usually 4-8 weeks. It also depends on mould size and structure complexity. Cavity…