Inspection Of Die Castings

The inspection of die castings is generally determined by both the supply and demand parties, and the general inspection items are:

A. Chemical composition and mechanical properties of die casting specimen shall conform to the requirements of gb/t15115.

B. The geometrical shapes and dimensions of die castings shall be in accordance with the casting drawings and dimensional tolerances according to gb/t6414.

C. The surface quality of die castings shall be smooth without cracks, loose, bubbles and any penetrating defects.

D. Other users need to test the project.

This is custom heading elementDescriptionFeedbackDescription Plastic Pumps This pump rotor is made of GFR PP, which is a good use for magnetic drive pumps, which are designed to improve people and plant safety. Especially when toxic, explosive or other dangerous liquids which react on contact with the atmosphere. It offer therefore exceptional benefits to the…

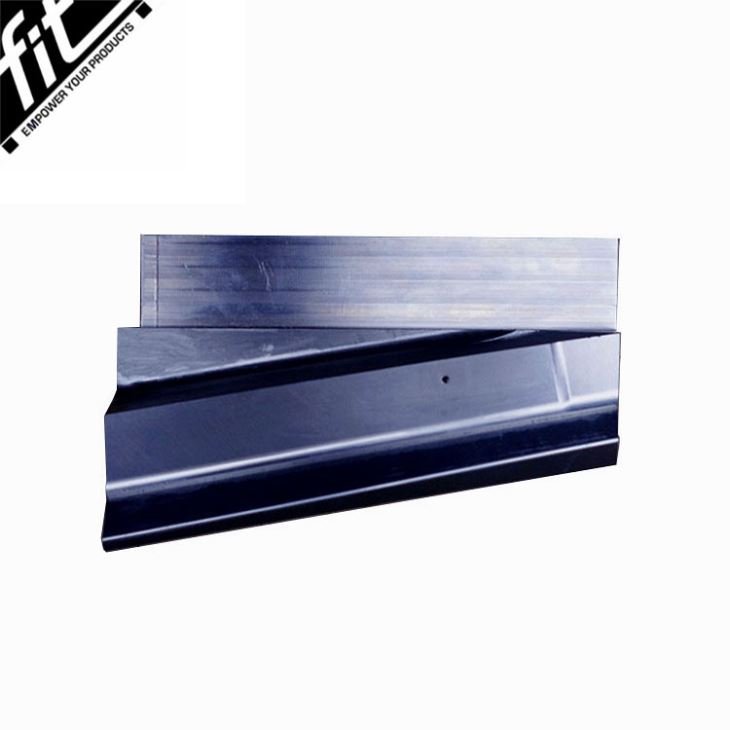

This is custom heading elementDescriptionFeedbackDescription Product Name: Plastic Injection Tool Material: Aluminum :ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100, etc Zinc alloy: Zmark3,Zmark5,ZDC3, etc Brass: HPb59-1,HPb62-1, etc Drawing format: CAD / PDF/ DWG/ IGS/ STEP/ X_T/ SAT /STL Process: Drawing & Samples → Mould making → Die casting → Deburring→ Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality…

This is custom heading elementDescriptionFeedbackDescription Application fields Automotive, Automation, Test systems, Sensors, Medical, Sports, Consumer, Home appliance, Electronic, Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, AOI, SMT equipment, etc Material Aluminum:5052 /6061/ 6063 / 2017 / 7075 / etc. Stainless Steel Alloy: 303 / 304 / 316…

This is custom heading elementDescriptionFeedbackDescription Rapid Prototyping for Sonography Equipment 1. Prototype making. To make the prototype via CNC machining. 2. Prototype checking and handling. Inspect the prototype size and structures, craftsman handle it, to remove any marks or deburrs ensuring the surface very good; Process cnc machining prototyping Our Advantage 1. Made according customer’s…

This is custom heading elementDescriptionFeedbackDescription Injection Molding Refrigerator Frame Customized plastic part 1.Plastic injection 2.Injection parts 3.Injection molding with high quality 4.Injection products design 5.Rich experience 6.Sample time:15~ 30days. 7.24-hour service with prompt reply More feature and specifications: 1.Mold and parts designing. 2.Mould and parts making 3.Mold machining 4.Injection molding 5.CNC prototype manufacturing…

This is custom heading elementDescriptionFeedbackDescription Part name Aluminium CNC Machined Auto Parts Surface treatment Electroplating Process CNC Miling Machining Process Packing Carton box Application Medical Equipment Finish Zn- Plated,Ni-plated, Passivated,Tin-plated,Sandblast and Anodize, Polish, Electro Painting,Powder coating,Chrome plated, etc. Production Way CNC Milling, CNC turning, Grinding, Wire cutting, EDM,Drilling, etc. Manufacturing Equipments HAAS CNC Machining Center, EDM Wire, Mirror…

This is custom heading elementDescriptionFeedbackDescription Monitor Rapid Prototype CNC machining monitor prototype Materials: ABS PC Process: CNC milling, polish, heating insert, coating, printing Tolerance: +/-0.05 – +/- 0.1mm Surface roughness: high polish and printing, Ni-coating Surface treatment: anodizing, hard anodizing, plating, polishing, heat treatment File format: 3D: IGS, PRT, STEP, STP, SLD 2D: DWG. CDR. PDF.…

This is custom heading elementDescriptionFeedbackDescription FIT PRECISION MOLD CO., LTD specializes in providing good design and high-precision products at product developing and producing area. Our professional staff are experienced at tool/mold making service including plastic injection mold (mould),die casting mold (mould) and metal stamping mold (die); At the same time we are involved in molded…