Happy Labor Day!

This is custom heading elementDescriptionFeedbackDescription Die Cast Motorcycle Wheel Hub Specifications: Item: Casting Hubs for Honda motorcycle Part material: Aluminum Surface finish: Powder Coating Color: Silver Tolerance: 0.01-0.05mm Inspection report and material test certifications are available upon requests Note: Customize size or pattern is available. Package: PP bag and Carton Box General Service range:…

This is custom heading elementDescriptionFeedbackDescription Plastic Pumps This pump rotor is made of GFR PP, which is a good use for magnetic drive pumps, which are designed to improve people and plant safety. Especially when toxic, explosive or other dangerous liquids which react on contact with the atmosphere. It offer therefore exceptional benefits to the…

This is custom heading elementDescriptionFeedbackDescription Product Design Begin with good design FPM has the unique ability to contribute value at every phase of your product development via our global technical expertise. With state of the art design services, the right tools and a full staff of experienced people on hand, FPM can help…

This is custom heading elementDescriptionFeedbackDescription Auto Battery Terminal Cover Over 10 years’plastic injection molding manufacturing experience, exporting to over 30 countries worldwide. Own ISO 9001:2008 certified factory with strict QC inspection system. OEM/ODM services & Customization service available. Production process and quality control process are approved by ISO 9001:2008 Inspection report and material test certifications…

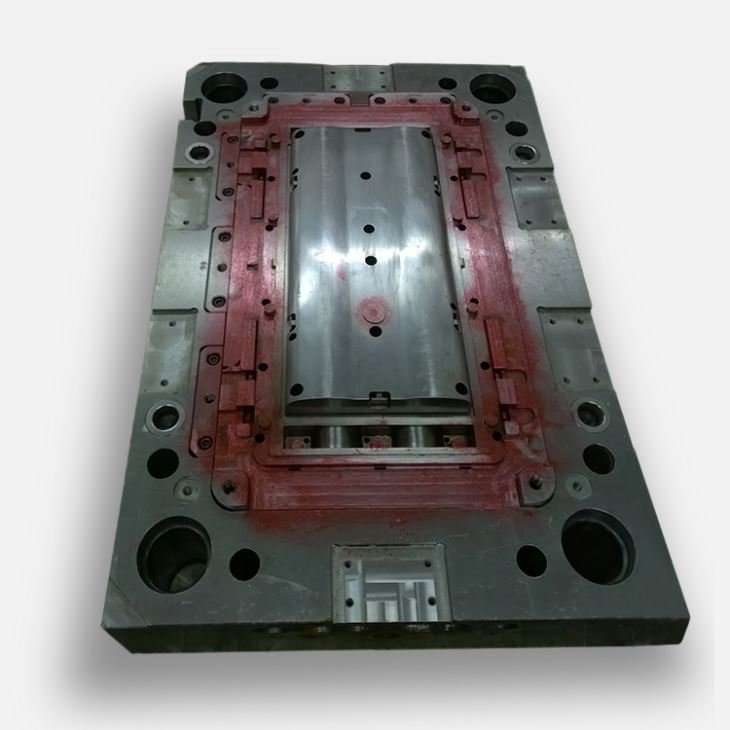

This is custom heading elementDescriptionFeedbackDescription Product Name Plastic Injection Molding Mold for Plastic Electronics Parts Auto Parts Mold shaping Plastic Injection molding Mold base LKM;HASCO;DME,etc Mold material NAK20,S136,P20.718H,738H,45#,etc Mold cavity Single or Multi Tolerance +/-0.02mm Finish Anodized,Polish,Silk-screen,Painting,etc Sprue gate Hot/cold runner;pin-point gate,etc Design software UG,PROE,CAD,SOLIDWORK,etc Product material ABS,PP,PE,POM,PMMA,etc Mold life 100000-500000 shots Lead time 25-45 days Transportation By sea, by air or by land as you request Package Standard or as you request OEM/ODM Acceptable Certificate ISO9001:1008,SGS, FAQ 1. Q: what is the…

This is custom heading elementDescriptionFeedbackDescription Product name Precision Injection Mold Tooling Mold Type Plastic Injection molding Mold base LKM;HASCO;DME,etc Mold material NAK20,S136,P20.718H,738H,45#,etc Mold cavity Single or Multi Tolerance +/-0.02mm Finish Anodized,Polish,Silk-screen,Painting,etc Sprue gate Hot/cold runner;pin-point gate,etc Design software UG,PROE,CAD,SOLIDWORK,etc Product material ABS,PP,PE,POM,PMMA,etc Mold life 300,000-1,000,000shots Lead time 25-45 days Transportation By sea, by air or by land as you request Package Standard or as you request OEM/ODM Acceptable Certificate ISO9001 FAQ Q1: Which kind information need for quotation? A1: 1) Sample photo with size or 2D/3D design 2) Product material 3) The quantity 4) Runner type, cold or hot 5) Mould steel type,…

This is custom heading elementDescriptionFeedbackDescription Shock Absorbing Seating Fit Precision Mold. Co.Ltd is a Professional shock mitigation seating components manufacturer, equipped with dozens of sets CNC milling machine, professional pipe benders. We can produce all kinds of shape, angle of bending tubes, provides the heat treatment, enhanced hardness. Our advantages 1. Professional shock absorbing…

This is custom heading elementDescriptionFeedbackDescription Product Name Industrial Injection Mold Mould material P20 steel, 718, 2738,H13, NAK80,2344,2343,S136,etc…. Fast mould design can be within 1-3 working days after getting customer’s drawings Lead time 3- 6 weeks after getting the mould design confirmation Mould testing All of the moulds can be well tested before the shipments. Videos…