Coin + Injection Molding Realizes The Production And Application Of Products

The opening ceremony of the first new Focus (C519) was held recently at the Changan Ford OEM in Chongqing, China.

This marks the latest product of Blonde Carbon Fibers, a continuous fiber reinforced thermoplastic composite that has been mass-produced for the first time in the field of automotive lightweighting.

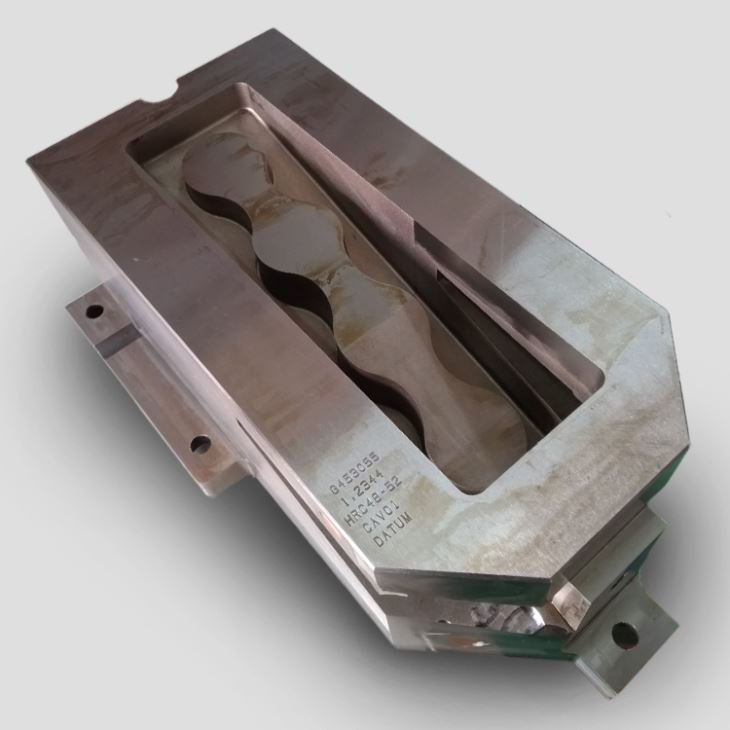

The door system supplier of Changan Ford C519, Germany Brose Company, innovatively adopts the combination of organic sheet composite material and LFT mixed material solution to replace traditional steel or single long fiber PP, supporting a new mixed process molding production line (molding + injection molding). The manufacture and manufacture of thermoplastic composite door substrates are realized.

Compared to steel and long-fiber PP door systems, thermoplastic composite door systems can effectively reduce weight by 5kg/car or 2kg/car. Due to the introduction of continuous fiber materials, the new door substrate design is lighter in weight, higher in strength and more efficient, and can integrate more functions and modules, saving production and installation of multiple sub-components and multiple welding processes, further reducing The weight and assembly work of the door system assembly.