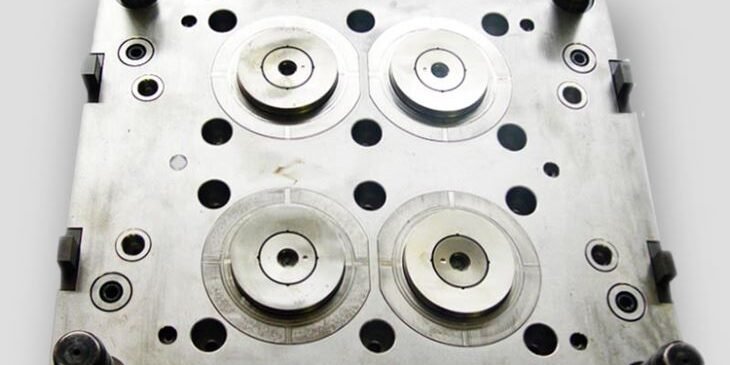

Precision OEM Injection Mold Making For Automobile Plastic Products

| Mould material | plastic |

| Cavity | 1 cavity/2 cavity / multi cavity |

| Runner | hot runner /cold runner |

| Mould life | 300,000-500,000 shots |

| Processing method | forings, CNC milling and turning, grinding, casting, broaching, etc |

| Design softwares | NX-UG, Pro/E, Moldflow, Auto CAD |

| Hardness of steel | 46~56HRC |

| A surface request | EDM&High polish |

| Payment terms | T/T, L/C, Paypal and so on |

| Production | pilot run production and molding production can be provided |

| Specification | More than 10 years machining parts processing experience; precision tolerance less than 0.001mm; depends on customers’ requirement |

| Processing equipment | CNC machine, Automatic lather machine, EDM machine, stamping lathes, wire-cutting machine, milling/grinding machine, punching/drilling machine, injection machines etc |

FAQ

Q: Does your company make mould by yourself?

A: Yes, we are manufacturer with about two decades of molding experience.

Q: How many kinds of moulds can you make? Only make the moulds?

A: We can make many kinds of moulds, such as plastic injection moulds. Blowing moulds, stamping moulds, die casting moulds and silicone rubber moulds. Besides, we also can produce the final parts for you.

Q: What’s the software you will use to check the drawing? And what’s format of drawing you can check?

A: Our designers and engineers all use AUTO CAD and solidworks software to check 2D and 3D drawings. We can check the drawings with PDF, AI, DWG(CAD) and STP(3D) or IGS(3D) formats, and so on.

Q: Will you send me the free sample?

A: Yes, but you should charge the freight by yourself.

Q: How to pack the moulds and products?

A: For moulds, we will coated one layer anti-rust oil first, and then also covered thin films on the mould, finally pack into non-fumigation wooden cats. And as to products, we will pack into standard export cartons or as per customers’ request to pack.