Airbag Cover Injection Molding

Airbag cover injection molding

Airbags have to be protected from damage to ensure their reliable deployment throughout the vehicle’s life cycle. The airbag protection solution should take up as little assembly space as possible and enable cost-effective production and assembly.

| Fit Precision Mold Co., Ltd | ||

| 1 | Company’s strength | 1) Efficient team 2) Delivery on time 3) Excellent equipment 4) High quality and competitive price |

| 2 | Core and cavity material | 718, 718H, S136, NAK80, P20, SKD61, etc |

| 3 | Plastic material | ABS, PE,PP, PET, EVA, PMMA, PC, PU, etc |

| 4 | Cavity Qty | Single-cavity/Multi-cavity |

| 5 | Plastic material for the parts | PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE |

| 6 | Design Software | Pro/engineer, Solidworks, UG, AUTO cad |

| 7 | Process | CNC, high speed carve, EDM, wiring-cutting, drill, polish |

| 8 | Quality | ISO 9001:2000 Certificate |

| 9 | Lead Time | 10-30 workdays depends on the different products |

| 10 | Package | Wooden Case Package or according to customer requirement |

| 11 | Price Term | FOB Shenzhen Port, China |

| 12 | Primary Competitive Advantages | 1) Quickly response and complete understanding 2) The most competitive and reasonable price 3) Short delivery time and prompt delivery 4) Well and High Quality Control 5) Customer’s Designs and Logos are welcome 6) In a variety of designs 7) Small order accepted 8) OEM acceptable |

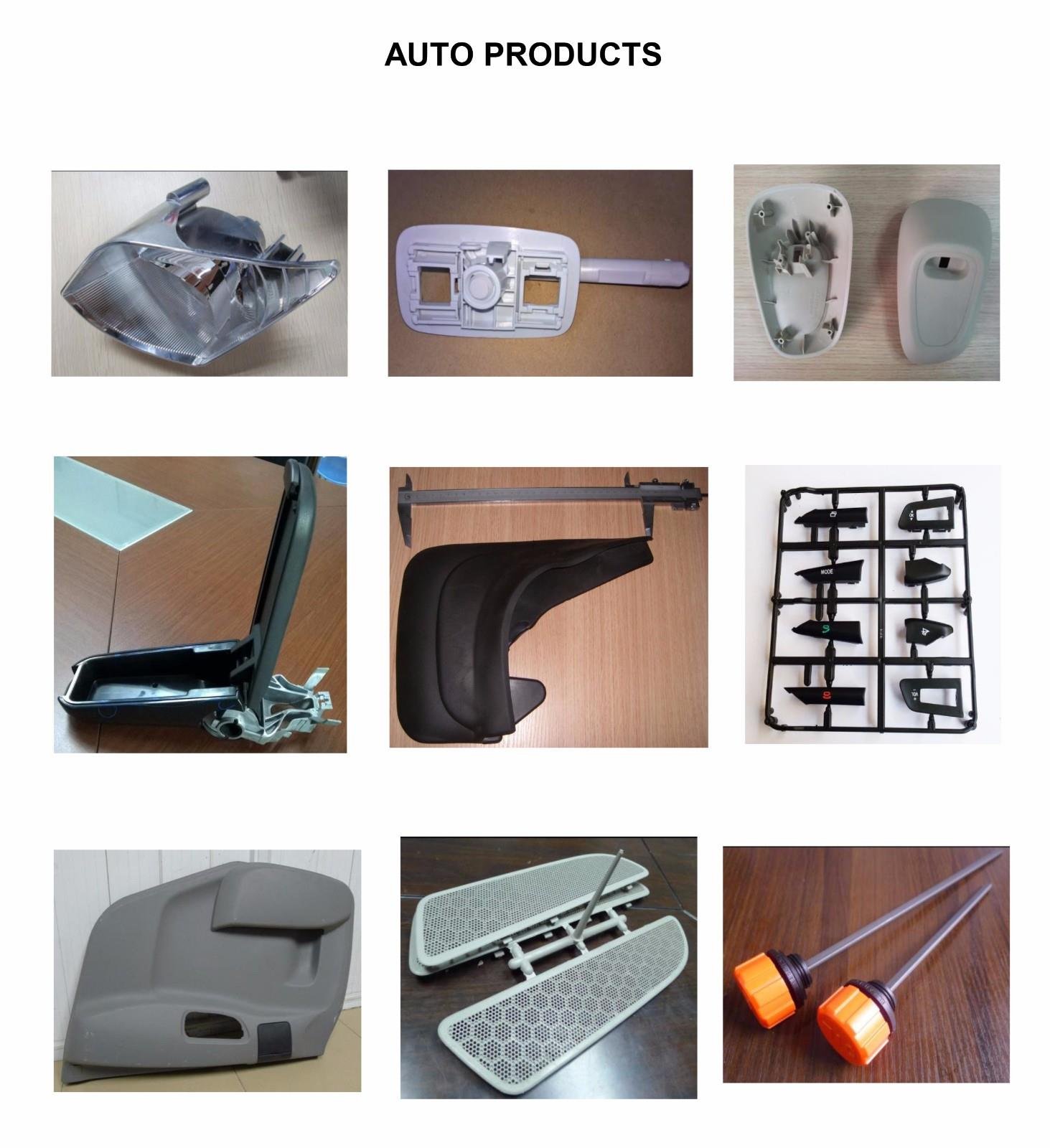

Auto Products