Engine Protection Plate Plastic Injection

FIT PRECISION MOLD CO., LTD has provided high quality tooling & molded parts for over 20 years.Our design & manufacturing process covers CAD, CAE, CAM, Prototyping, 3D printing, plastic injection molding, metal casting, rubber compression.

Thanks to globalization and peace, we are honored to work together with great world-class famous enterprise Auto industries “FORD” “BWM” “PSA” “Visteon”..etc, Design industries “McKinsey”, “D+I”, “Lunar”…ect, Electronics industries “Sony”, “Huawei”, “Motorola”…ect. Our turn key solution will help you to shorten Supply chain cycle and save cost.

Specification:

| Fit Precision Mold Co., Ltd | ||

| 1 | Mould Base | LKM, Hasco, DME, and others |

| 2 | Cavity and core material | 2738, 2343, DIN-1, S130, H13, 2344, 738H, 718, 8407, S136, NAK80,P20 etc |

| 3 | Treatment | Pre-Harden, Nitriding, Heat treatment, Quenching |

| 4 | Cavity Qty | Single-cavity/Multi-cavity |

| 5 | Runner | Hot runner or Cold runner :YUDO/ MASTIP/ HASCO/ DME/ FISA/HUSKY/MOLD-MASTER/SYNVENTIRE/ANNTONG |

| 6 | Gate | Submarine gate, side/edge gate, direct gate |

| 7 | Plastic material for the parts | PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE |

| 8 | Mould Life | 500K – 5 million shots at least |

| 9 | Drawing files format | UG, PRO/E, SOLIDWORKS, CAITA, CAD, STP, X_T, IGS, PRT, DWG, DXF, PDF, etc |

| 10 | Process | CNC, high speed carve, EDM, wiring-cutting, drill, polish |

| 11 | Quality | ISO 9001:2000 Certificate |

| 12 | Lead Time | 10-30 workdays depends on the different products |

| 13 | Package | Wooden Case Package or according to customer requirement |

| 14 | Price Term | FOB Shenzhen Port, China |

| 15 | Payment | T/T, L/C, western union, money gram |

| 16 | 15 years professional manufacture experience, We are specialize in design and manufacture of plastic injection mould (tooling) for Automotive, electrical appliances, house wares, medical devices, Toys and Games, Communication industries | |

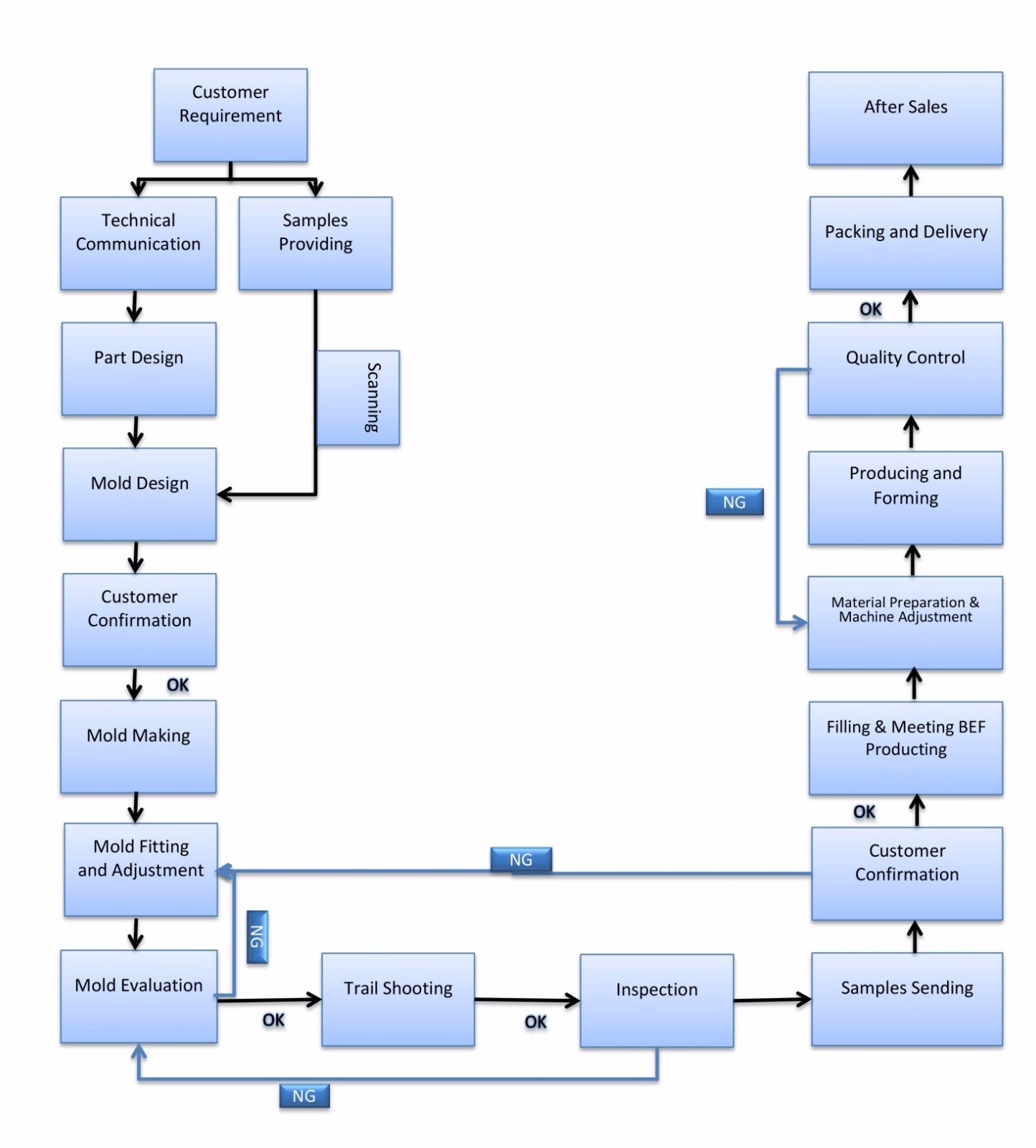

Fitmold Working Flow

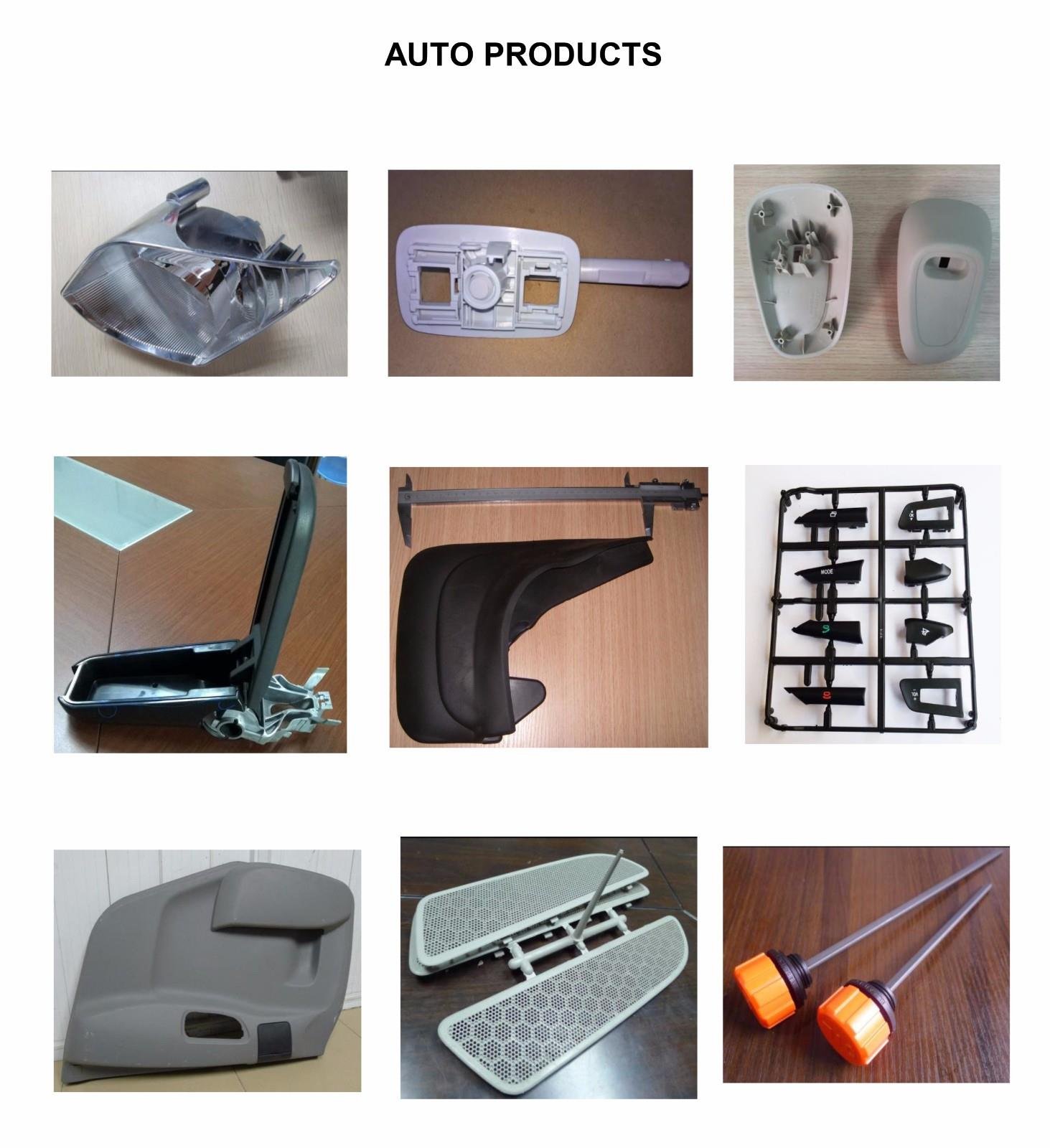

Auto Products