Plastic Injection Molded Oil Dipstick

FIT PRECISION MOLD CO., LTD has provided high quality tooling & molded parts for over 20 years.Our design & manufacturing process covers CAD, CAE, CAM, Prototyping, 3D printing, plastic injection molding, metal casting, rubber compression.

Thanks to globalization and peace, we are honored to work together with great world-class famous enterprise Auto industries “FORD” “BWM” “PSA” “Visteon”..etc, Design industries “McKinsey”, “D+I”, “Lunar”…ect, Electronics industries “Sony”, “Huawei”, “Motorola”…ect. Our turn key solution will help you to shorten Supply chain cycle and save cost.

General Information

| Item# | Item | Description |

| 1 | Mold standard | DME, HASCO, Misumi etc |

| 2 | Mold Base | LKM,DME, HASCO, FUTABA |

| 3 | Cavity/Core Steel | H13,S-7,S136,SS420,NAK80,P20 |

| 4 | Hot Runner: | MOULD MASTER, HUSKY, HASCO, DME, YUDO, INCOE, THERMOPLAY, SYNVENTIVE. |

| 5 | Hydraulic Cylinder | PARKER, TAIYO, STAUBLI, JUFAN |

| 7 | Steel Treatment | Heat Treatment, Nitriding, Chrome Plating |

| 8 | Surface Finish: | SPI standard, VDI EDM, Texture, etc |

| 9 | Texture: | Mold-tech, Yick Sang, Ni Hong ,Tanazawa etc |

| 10 | Plastic Material | PP, PC, ABS, PE, HDPE, PET, POM, PMMA, PA(GF), PBT(GF), PVC, PPS, PEI, PEEK, LCP, PSU |

| 11 | Design Software: | CAD, UG, Pro E, Solidworks |

| 12 | Value-added Service: | Dust-free Spraying, Silk-screen Printing, Ultrasonic Welding, Thermal Bonding, Assembling, Prototype |

| 13 | Export Country: | Europe, USA, Canada, Australia , India etc |

| 14 | Our Capability: | Auto, Aerospace, Household, Electrical, Industrial, Medial, Toys, Office, Cosmetic, Outdoor etc |

Description

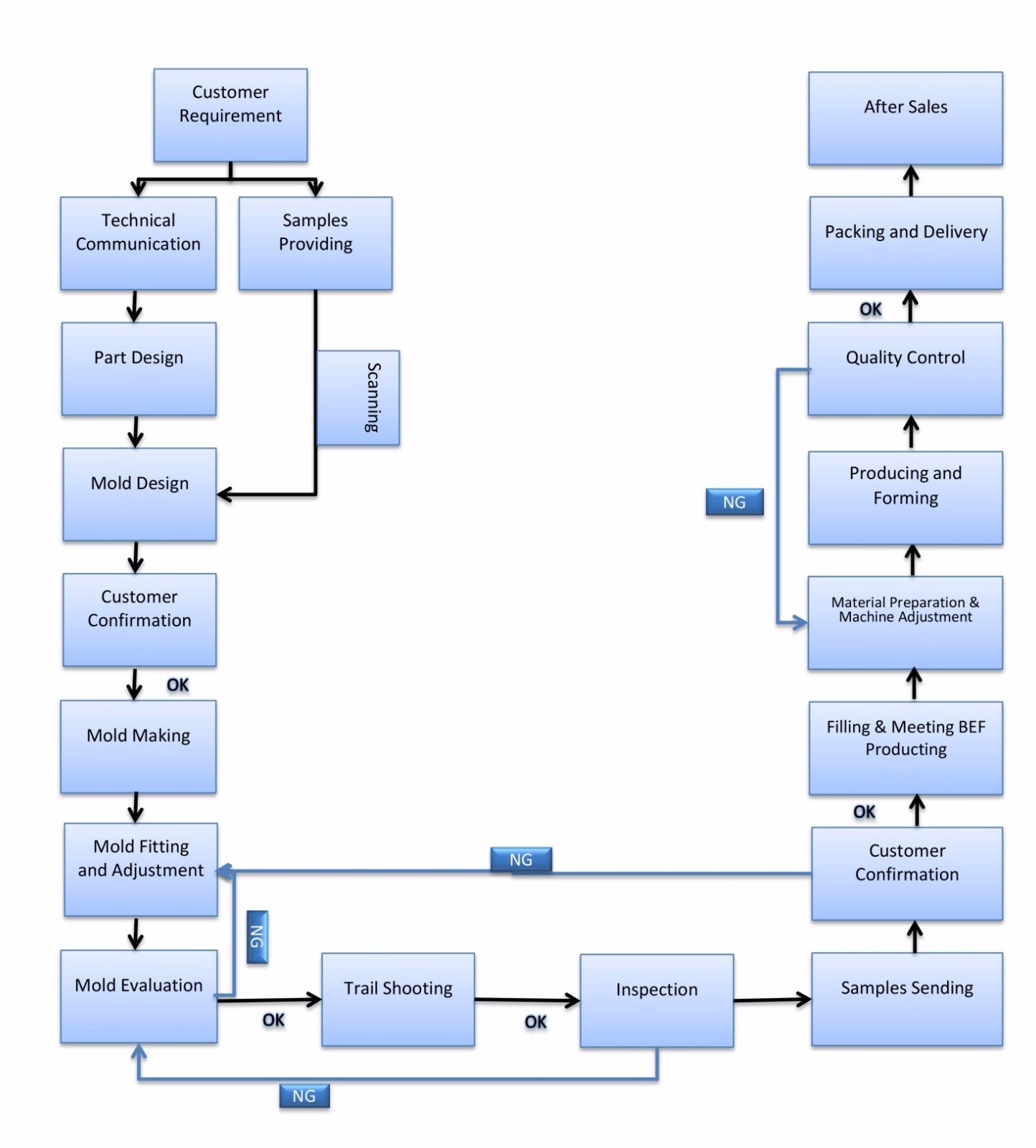

1.Quotation:We offer you the mould and part quotation according to your details(drawing or sample,material,quantity,weight).

2.Order: If our quotation is competitive,you will place the order.

3.Drawing design: We design the mould structure drawing according to your product drawing or sample,then send to you for confirmation.

4.Mould making: After your confirmation of our drawing,we begin to make the moulds,during manufacturing program,we send you mould building progress with pictures every week,for you to know our process.

5.First trial: We will make the mould first trial on time, then send you video, picture and samples for you to confirm.

6.Quality confirm: You will confirm our mould quality according to sample. If you need to adjust the product structure,we can help you change the mould further.

7.Delivery: Ship the mould after it is completely OK,packed by wooden case.

Production Equipment

Production Equipment