Palm Silicone Rubber Use

Hand silicone for the production of hand models, PVC plastic mold, cement products mold, low melting point alloy mold, Alloy toys technology, plastic toys, electronics, handicrafts, stationery industry, large statues, cultural relics reproduction, (shoe mold) sole mold manufacturing, pad positioning, electronic equipment, such as the design of seismic products model development, Turn the number of times about 5-10 times, is used to do simple pattern products, toys, car Aberdeen.

This is custom heading elementDescriptionFeedbackDescription Item High Precision CNC Machined Unmanned Aerial Vehicle Accessories Materials Iron, aluminum, steel, copper, plastic, carbon steel, nylon, bronze, solder alloy, HSS, tool steels, or as per the customers’ requirements. Dimensions According to customer’s drawing Surface treatment Heat treatment, polishing, powder coating, galvanized, electroplating, spraying, and painting and so on. Packing Wooden box, or as per the customer’s requirements Processing equipments CNC machining center, CNC lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project To provide production design, production and technical service, mould development and processing, etc. Testing machine Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity Negotiable Payment T/T 50% deposit ,and 50% T/T before shipment (detailed case can be discussed) Business scope CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc Application Automation machine, medical device, industrial machine, automobile, electric appliance, and other industries. Min order and sample order is acceptable. Machining service as per your requests and specific drawings, either small or large quantity is acceptable for us. We are sincerely expecting to cooperate with you. Send InquiryFeedback

This is custom heading elementDescriptionFeedbackDescription Car Model Scene Platform An automobile model (or car model or model of car, and typically abbreviated to just “model”) is a particular brand of vehicle sold under a marque by a manufacturer, usually within a range of models, usually of different sizes or capabilities. Fit Precision Mold Co., Ltd…

This is custom heading elementDescriptionFeedbackDescription Overmolding Plastic Cover Overmolding is also called 2 timesinjection molding in China. Compared with the third-party material bonding, overmolding process makes the process faster and more cost-effective, it has been widely employed in plastic design. Base information Company Fit Precision Mold Co., Ltd Main product plastic mould, tooling, prototype,…

This is custom heading elementDescriptionFeedbackDescription Item Name Injection Molds for Plastic Water Pumps We produce Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration Pls provide 2D, 3D, samples, or the size of the multi-angle pictures Mould Time 20-35 Days Product time 7-15 Days Mould precision +/-0.01mm Mould life 50-100 million shots Producing Process Audit drawings…

This is custom heading elementDescriptionFeedbackDescription Aluminum Fixed Clip Wide material choices: From normal engineering grade plastic to aerospace grade light strength aluminum, even high performance steel, we can finish the required part with the required material. We made thousands of part made from ABS, PC, PMMA, NYLON stainless steel 201, 303, 304, 316, carbon steel,…

This is custom heading elementDescriptionFeedbackDescription FIT PRECISION MOLD CO., LTD has provided high quality tooling & molded parts for over 20 years.Our design & manufacturing process covers CAD, CAE, CAM, Prototyping, 3D printing, plastic injection molding, metal casting, rubber compression. Thanks to globalization and peace, we are honored to work together with great world-class famous…

This is custom heading elementDescriptionFeedbackDescription Material: 100% silicone or natural rubber or PU Hardness Range: 30-90 Shore A Features: 1.Oil-resistant; heat resistant; abrasion-resistant; aging resistant; insulation; acid and alkaline resistant; airtight; shock absorption, etc. 2. 100% food grade silicone with FDA & LFGB approved. 3. Accept OEM and ODM orders; 4. Over 10 years experience in…

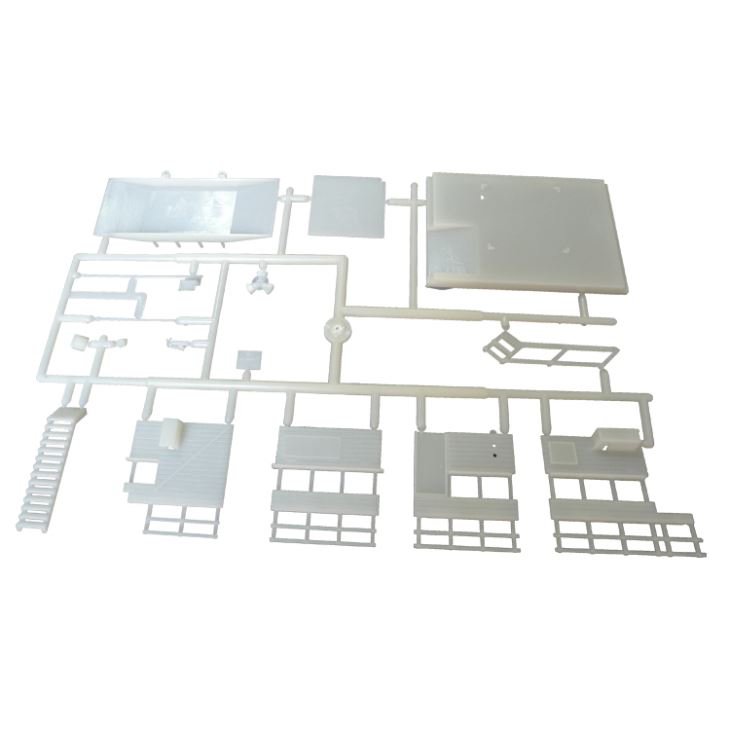

This is custom heading elementDescriptionFeedbackDescription Product Name Plastic Injection Molding – Tool Building – Mold Design & Analysis mould material 45#,P20,H13,718,2738,NAK80,S136. mould base LKM,HASCO Cavity 1 or more Runner cold or hot runner Mould life 45# :300,000-500,000shots P20: 500,000shots 718: 700,000shots Design software UG,PROE,CADetc. Plastic material PP,PE,ABS,PC PET pa66 . Delivery time 30 days Specification with good quality lower price FAQ 1. Q: How long is the lead-time for a plastic injection mold? A:…