Internationalisation Of Production Leads To Global Competition

The internationalisation of production has led to an increasingly competitive business situation for European tooling companies. This can be traced back to two main causes. On the one side, non-European competitors from low-wage countries have entered the European market with low-priced tools and dies. On the other side, growing economies all around the world have developed large selling markets, leading to an increased scattering of the tool and die industries’ customer base.

This is custom heading elementDescriptionFeedbackDescription Power Supply Pillar Company Information Fit Precision Mold Co., Ltd has evolved to be one of the leading customer injection molders in our region. Fitmold engaged in the development, design and manufacture of precise plastic mold and plastic parts, and specialize in offering all-around service for customers such as the…

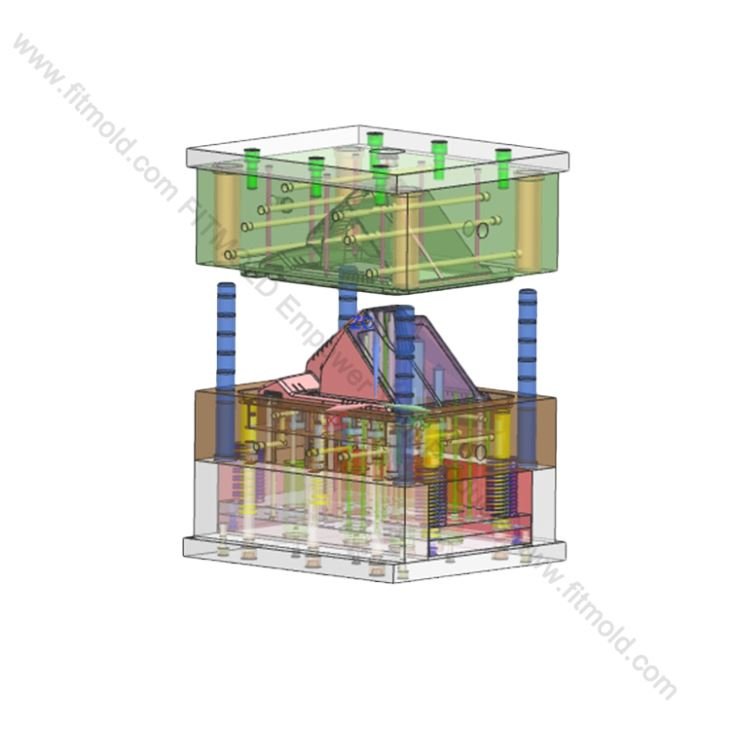

This is custom heading elementDescriptionFeedbackDescription Mold Design As a leader in the plastic injection mold industry, we believe that a quality part comes from a high quality mold and a good part design, and a good mold design are the keys to get a high performance mold. Quality must begin with mold design capability and…

This is custom heading elementDescriptionFeedbackDescription Name Silicone Interchangeable Colorful Watch Band, Rubber Belt Material 100% high quality silicone material with SGS certificate, Eco-friendly, harmless, non-toxic Specification Hardness: 50 shore A,tolerance can be ±5 shore A any color or size or design are available MOQ 100PCS LOGO Debossed noly, debossed color filled, embossed only, embossed color print, Laser logos , silkscreen…

Stamped Anchor Frame for Door ComponentsDescriptionFeedbackDescription Stamped computer housing made as clients’ drawing Die type: Progressive die. Raw materials: DC zinc coated, S/S, cold steel, copper, brass, aluminum, all variant raw material available. Surface finish: Powder coating Tooling lifespan: 1 million Feeding machine and stamping machine are used We have our own maintenance team…

This is custom heading elementDescriptionFeedbackDescription Blood Analyzer Our company is specialized in plastic injection mold making and plastic injection molding manufacturing, applied for medical equipments such as haematology analyzer, hematology cell counter, blood cell analyzer and son on. Advantages: Mold design is subject to customer’s requirement Injection molding machine utilizing certain specification of plastic…

This is custom heading elementDescriptionFeedbackDescription Model Truck Kits A model vehicle or toy vehicle is a miniature representation of an automobile. Other miniature motor vehicles, such as trucks, buses, etc. are often included in this general category. Fit Precision Mold Co., Ltd is specialized in producing all kinds of plastic scale model cars and accessories…

This is custom heading elementDescriptionFeedbackDescription Display Frame for Orion Welders Mold Material 45#, P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc. Mold Type Plastic Injection Molding Product Material ABS Mold Standard HASCO, DME, MISUMI, JIS, LKM, etc. Mold Tooling Equipment Lathe, Milling, Grinder, Drill, CNC, EDM, Wire cut machine, Punch machine Injection Mold…

This is custom heading elementDescriptionFeedbackDescription Fit Precision Mold Co.,Ltd offers a single-source global solution that supports any size company’s low- to high-volume molding needs. In-house experts working side-by-side are improving the injection mold business model—accelerating the quoting process, as well as including DFM (design for manufacturing) overview with every initial quote. Learn more about our tooling…