A Vital Technique-Heat Treatment

Heat treatment is an industrial process that is used for changing the physical and at times the chemical properties of a material. In the manufacturing segment, this process is commonly used in order to change metallurgical properties. The metal is heated in a furnace up to 2,000-2,700°C, which results in the absence of air as well as other gases, so that contamination does not takes place. Various industries such as automotive, aerospace and general machinery make use of this process to develop high precision products.

This is custom heading elementDescriptionFeedbackDescription Boat Battery Charger Company Information Fit Precision Mold Co., Ltd has evolved to be one of the leading customer injection molders in our region. Fitmold engaged in the development, design and manufacture of precise plastic mold and plastic parts, and specialize in offering all-around service for customers such as the…

This is custom heading elementDescriptionFeedbackDescription FIT PRECISION MOLD CO., LTD specializes in providing good design and high-precision products at product developing and producing area. Our professional staff are experienced at tool/mold making service including plastic injection mold (mould),die casting mold (mould) and metal stamping mold (die); At the same time we are involved in molded…

This is custom heading elementDescriptionFeedbackDescription CNC Machined Steel Ring Material: Aluminium6061/6063/7075/5052etc, Stainless steel303/304/400/316, SteelQ235, 20#, 45#etc, Brass:C36000(C26800), C37700(HPb59), C38500(HPb58), C2200(CuZn37), C28000(CuZn40) etc, Copper; Beryllium bronze copper. Platic material: POM, PA6, PA66, ABS, PC, PMMA etc. Process: CNC turning, CNC milling, CNC grinding;CNC lathe machining, CNC boring;CNC drilling, surface treatment Surface treatment: Hardness anodizing black/clear, steel…

This is custom heading elementDescriptionFeedbackDescription FIT PRECISION MOLD CO., LTD specializes in providing good design and high-precision products at product developing and producing area. Our professional staff are experienced at tool/mold making service including plastic injection mold (mould),die casting mold (mould) and metal stamping mold (die); At the same time we are involved in molded…

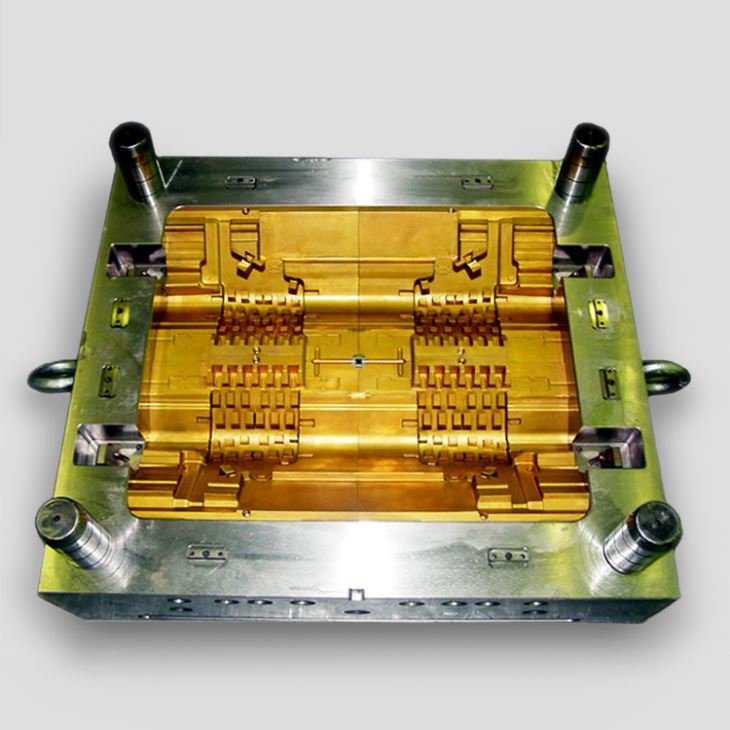

This is custom heading elementDescriptionFeedbackDescription Product description Advantages: 1. Competitive price 2. Strict quality control system 3. Quick mold making and delivery 4. Advanced equipment, excellent R&D teams 5. Professional technicians and rich experienced workers Item Description 1.Mould material P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 2.Hardness of steel vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 3.Inserts / Slider steel…

This is custom heading elementDescriptionFeedbackDescription What’s the details of plastic injection molds? Mould material P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . Runner Cold runner. Hot runner: Yudo/DME/HASCO Certificate ISOTS16949 Standard HASCO, DME, LKM Specification drawings Pro/E, Auto CAD, Solidworks, UG, CAD/CAM/CAE. Precision machining CNC, milling machine, drilling machine, numerical lathe,…

This is custom heading elementDescriptionFeedbackDescription FIT PRECISION MOLD CO., LTD has provided high quality tooling & molded parts for over 20 years.Our design & manufacturing process covers CAD, CAE, CAM, Prototyping, 3D printing, plastic injection molding, metal casting, rubber compression. Thanks to globalization and peace, we are honored to work together with great world-class famous enterprise…

This is custom heading elementDescriptionFeedbackDescription Rubber Diving Fins Fit Precision Mold Co.,Ltd started to do rubber compression molds at the year of 2004. Now we have a rich experience of compression tooling making and rubber/silicone parts making. Item Rubber Swim Fin Material NR, NBR, EPDM, SBR, CR, FPM, silicone and so on Size…