All-Electric Injection Molding Machine Achieves Higher Production And Flexibility

The manufacturing unit of the injection molding machine is integrated with a positioning unit controlled by a servo motor. In KraussMaffei’s full range of all-motor PX 320 injection molding machines, servo motor-controlled positioning units extend the clamping force range to 3200 kN.

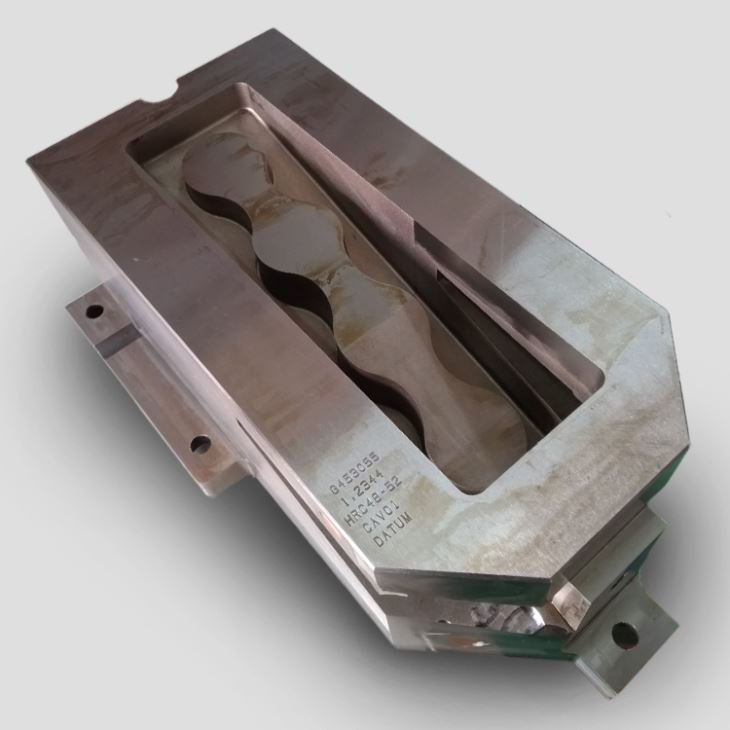

The all-electric injection molding machine is especially suitable for injection molding of complex parts, because the whole motor injection speed is faster and the precision is higher. After the injection molding, other surface decoration processes can be automatically performed.

In the in-mold decoration process, the PX 320 injection molding machine can cut and peel the nozzle material in the laser cavity developed by Datatronik, and then automatically transfer the nozzle material to the waste collection box, and finally the conveyor belt with UV lamps. The curing of the scratch resistant layer is completed.

The entire plant is designed to be very compact, with industrial robots that can be precisely operated in a small space, so there is room for an optional dust cover, allowing the entire production process to be carried out in a clean environment.

“The new PX with IMD SI DUO equipment is able to increase throughput in multi-cavity molds and make product production more flexible,” concludes Mitzler.