Gimatic Exhibits EOAT And Other Mold Removal Components

At Fakuma 2018, Italy’s Gimatic S.r.l. shows a range of mechanical components in the plastics industry.

Since its inception in 1985, Gimatic’s self-positioning has not been a business as a research and development, product offering, but a solution to improve efficiency, extend service life and reduce waste.

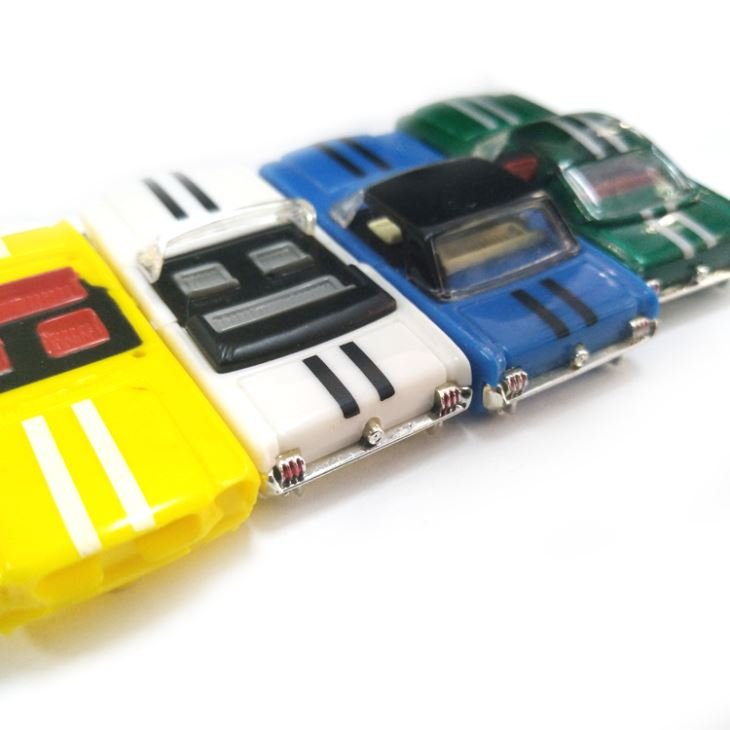

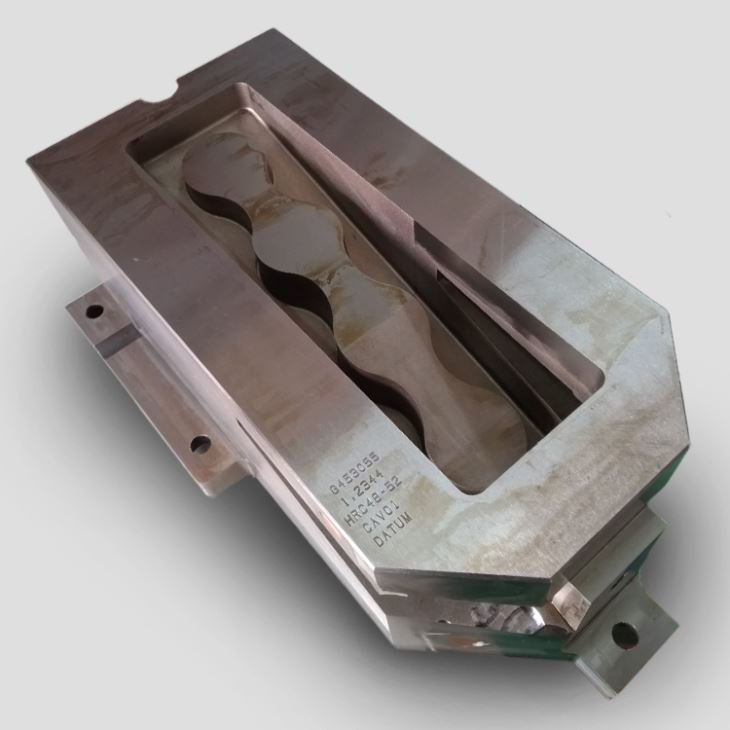

It includes all of these components, which can be combined into a unique fixture system in an infinite combination, enabling any type of robot or robot to efficiently and safely remove the injection molded product from the mold.

These End of Arms tools, also known as the international acronym EOAT, are ideal for operators handling products without damaging the product, moving the product as quickly as possible or inserting it into a finishing cycle or assembly operation.

From the smallest components in the pharmaceutical and electronics industries (tributing to fixtures, vacuum cups and small suspensions) to large objects in the household goods or automotive industry (with frame, slider and guide rails for superior precision and high load capacity), Gimatic The global framework provides an integrated solution from the robot arm to the smallest peripheral trimming pliers.