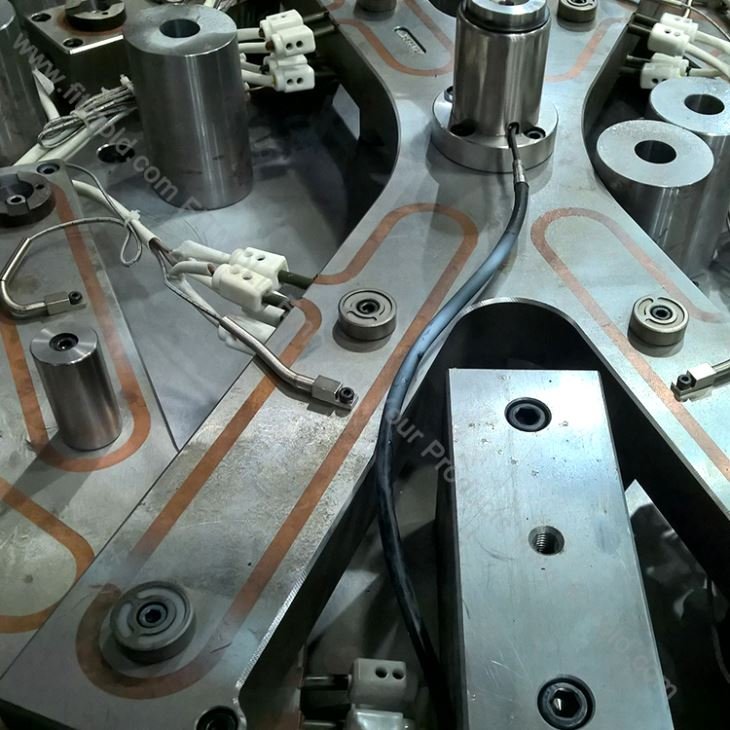

Hot Runner Injection Mold

Hot Runner Injection Mold

Hot runner solutions have been widely applied in various injection molded plastics, such as bumpers, automotive, or LCD/TV panels. The advantages include material and energy saving, shorter cycle time, reduced injection and clamping force, etc. However, a hot runner system is comparatively more complex and commonly faced with the challenge of temperature control and the risk of thermal degradation of plastic materials.

| Main Technique Parameters | |

| Cavity/Core Material | 718H, P20, NAK80, 2316,2738,Din2344,H13 and available |

| Product Material | ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc. |

| Base | LKM or by requested |

| Structure | Double color injection mould, Solid Mould, Insert Mould, Mould with Slide, Mould with Lifter |

| Runner System | Hot runner, Cold runner |

| Cavity | Single cavity, multi cavity by requested |

| Mould standard | HASCO, DME, MISUMI, or by requested etc. |

| Software | CAD, Pro-E, UG, etc |

| Tolerance | +/- 0.05mm |

| Design Time | 3-7days |

| Sample time | 3-7days |

| Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, and 2.5 Dimension test, etc. |

| Production time | 2-7 weeks, depends on mould structure |

| Packing | Wooden case, or by requested |