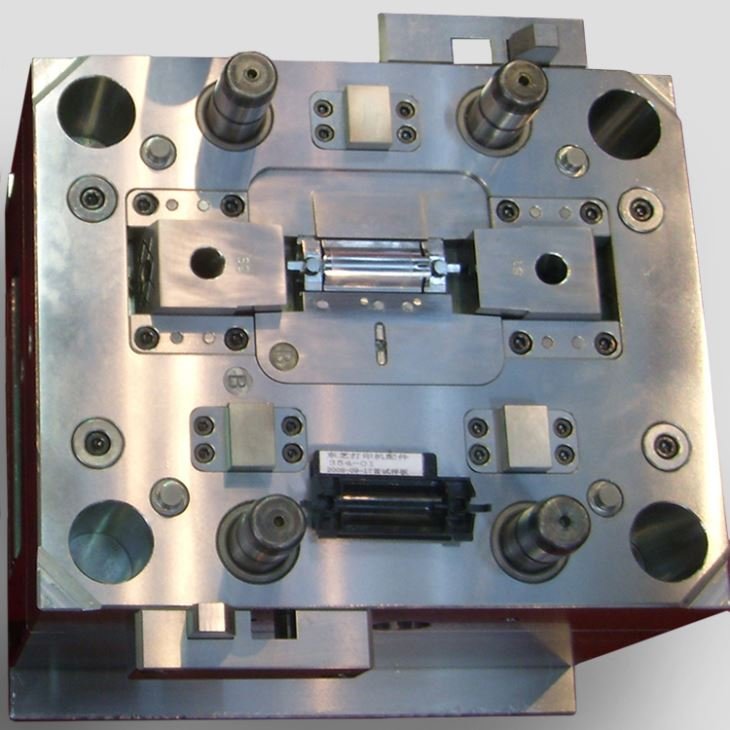

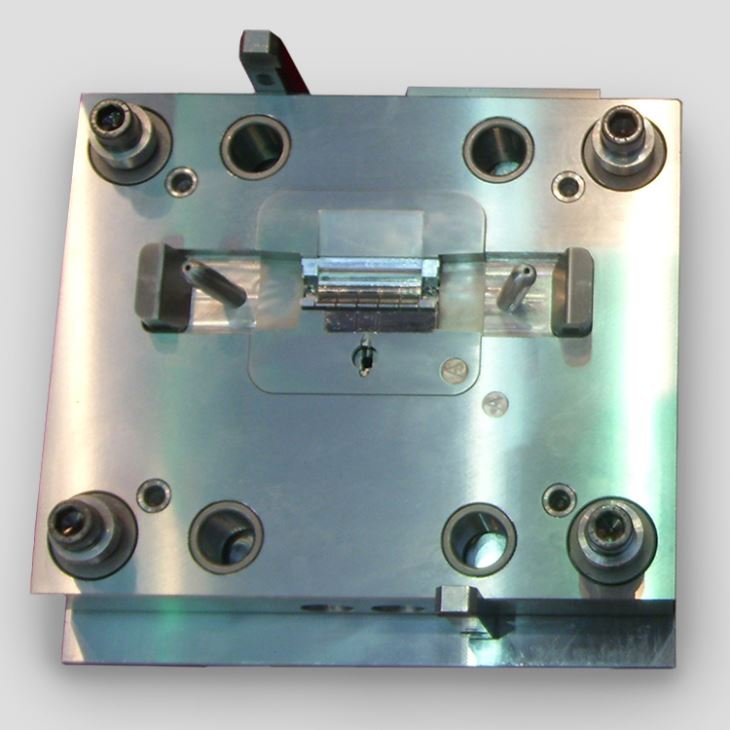

| MODEL: | Printer Accessories Plastic Injection Mold |

| Tolerances Optional: | a) Fractions ±1/16 | b) Decimals X.XX ±0.01 | c) Angles X.X ±0.1 |

| Material Optional: | a) mold base: S50C steel or P20 |

| b) Mold Cavity steel: 738,718H,8407,NAK80,S136,etc. |

| c) Mold Core steel: P20,H13,718,2738,NAK80,S136,etc. |

| d) Mold components: LKM,DME or HASCO standard. |

| Surface finishing: | a) Texture or Matt finish | b) Gloss & Mirror finishing |

| Runner system: | a) Cold runner system | b) Hot runner system |

| Mould lifespan: | a) Soft mold is less 300,000 shots | b) Hard mold is around 500,000-1,000,000 shots |

| Package : | a) PE film [transparent EPE bag] |

| b) Export standard wooden box |

| c) certificates of the steel and hot runner certificate |

| Additional: Manual of the tools and some spare components if needed |

| MOQ: | 1 set, it depends on your need. |

| Payment Terms: | a) T/T | b) L/C | c) Paypal | etc |

| Warranty: | a) one year against manufacturing defect |

| b) offer lifetime consultation on problems occurred |

| Lead Time | From 15 days to 40 days. It depends on the size and the structure of the mold. |