Different Types of Gates for Injection Molding

Gate design plays an important role in plastic injection mold design. The location, size, and shape of a gate has a significant effect on a finished product whether from product structure or appearance.Fit Precision Mold Co.,Ltd summarize some types of gates, which is commonly used in injection molding.

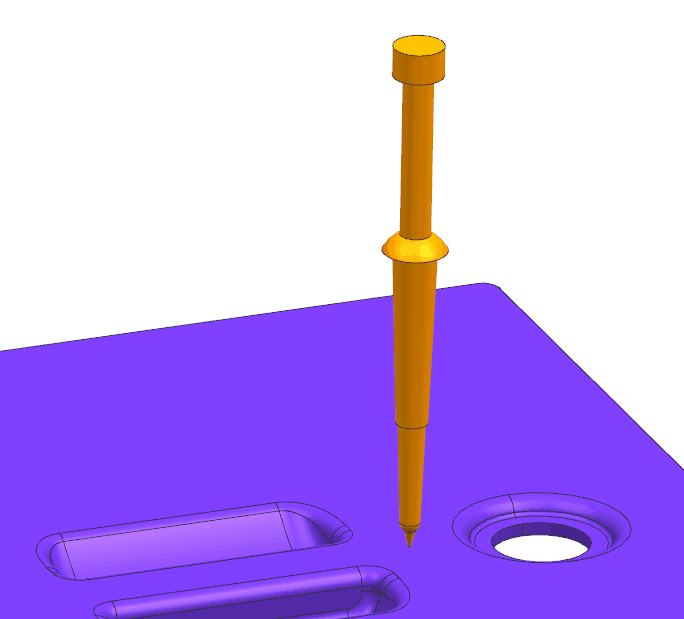

Pin-point Gate: It is a gate with a small cross-sectional area like a needle. It is generally used for plastics with better flow. The length of the gate generally does not exceed its diameter. Therefore, the gate is automatically cut off after demolding. It’s helpful to add a parting surface on mold, which facilitates the ejecting of gate. The disadvantage is that the small gate is easy to cause pressure loss, and some defects (flow marks, burnt, black spots) are generated during molding. Shape of point gates includes single point, double point, and multipoint etc.

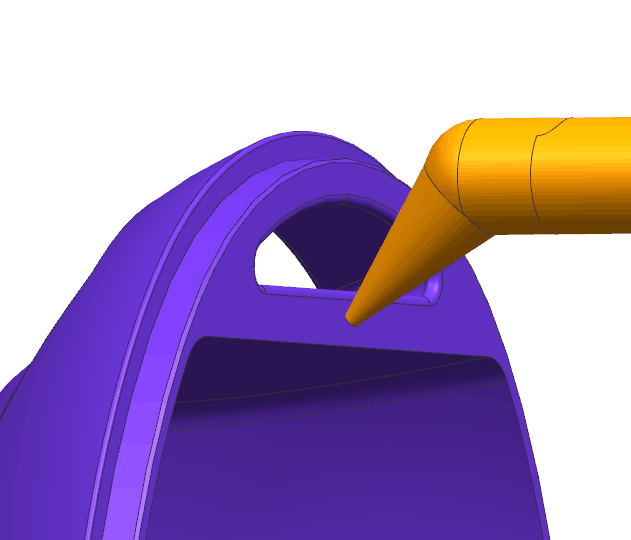

Edge Gate: Generally opened on one side of the mold, it’s injected from the inside or outside of parting surface, and the cross section is mostly rectangular, which is suitable for one mold with multiple cavities.

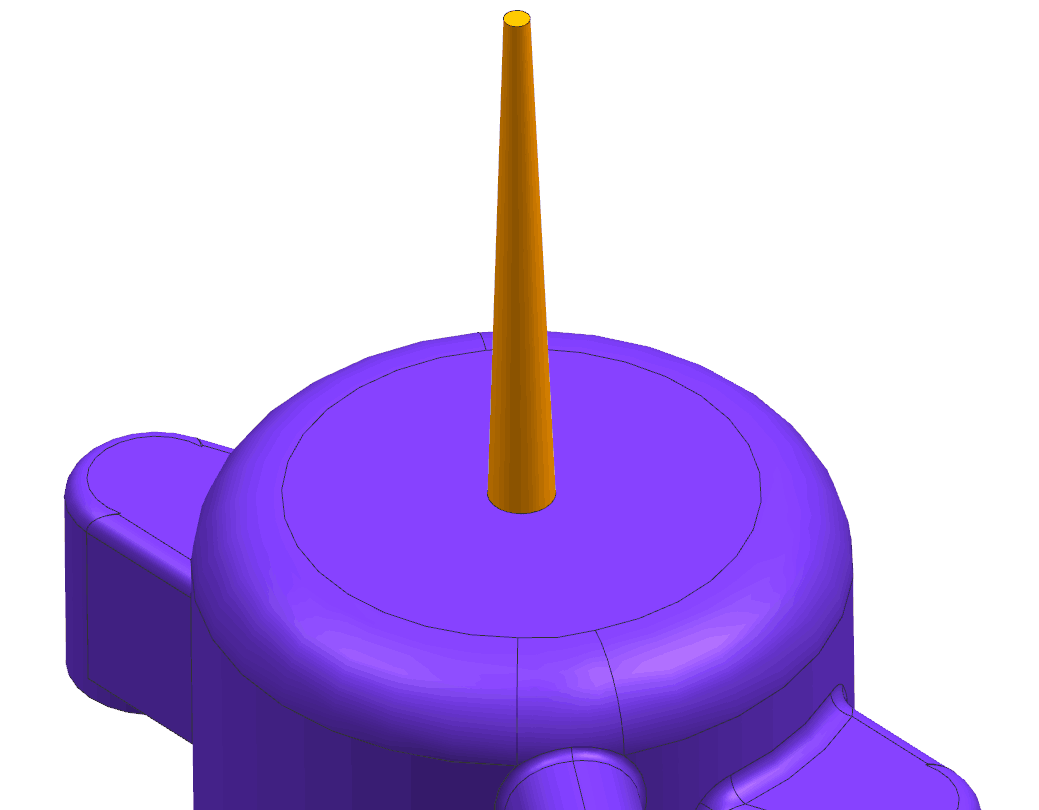

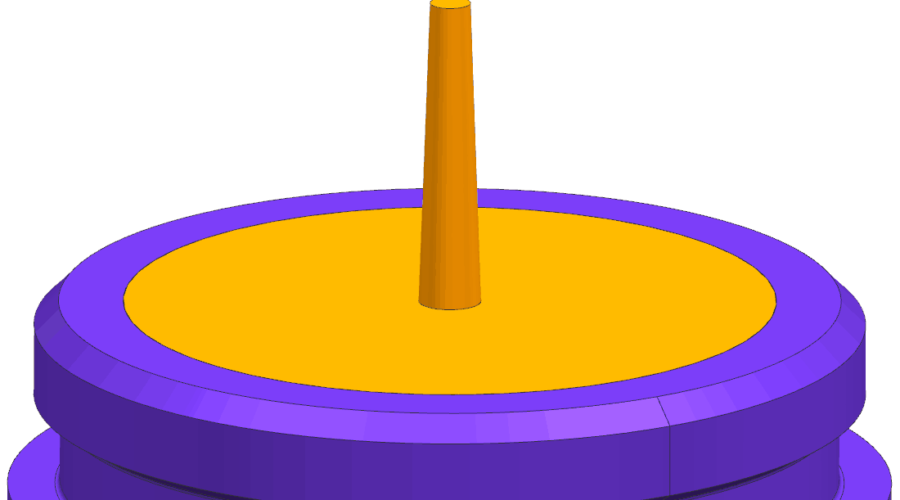

Direct or Sprue Gate: It enters the cavity directly from the main runner, which is suitable for deep single-cavity shell-shaped or box-shaped molds. The flow path of the runner is short and the pressure loss is small, which is conducive to exhaust, but it is inconvenient to remove the gate and will leave obvious marks.

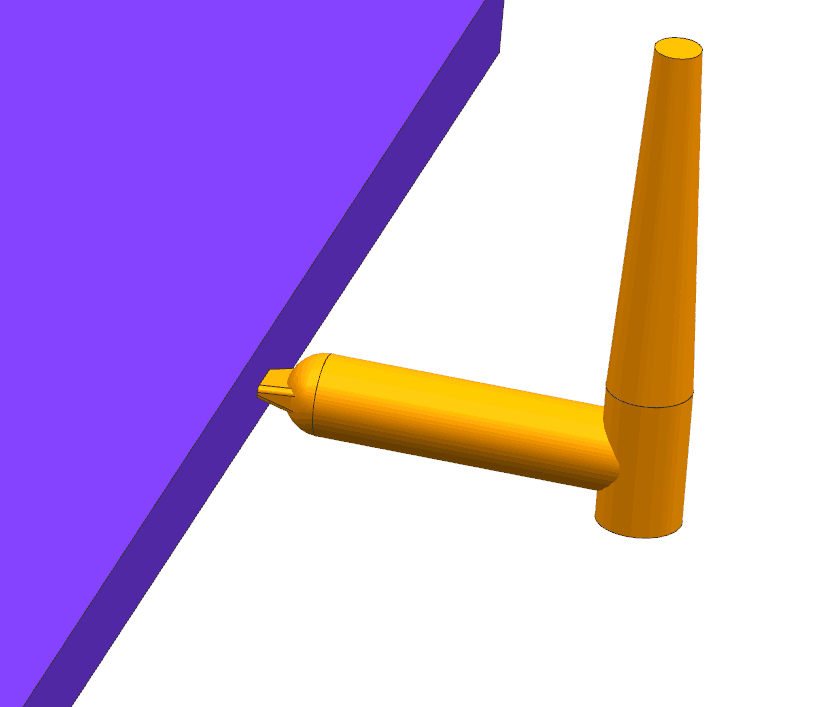

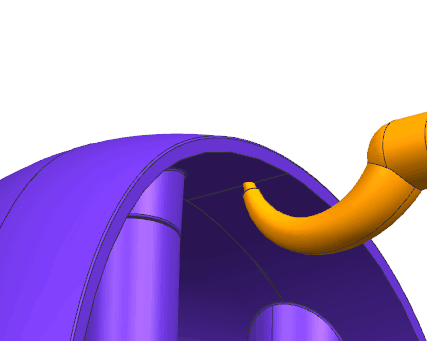

Submarine Gate: The gate is inclined and lurks on one side of parting surface, and the pin point gate can be automatically cut off when material is injected on the side or inside of the product, which is suitable for automated production.

Banana Gate: Much like a submarine gate, the banana gate is machined below the parting line and is automatically sheared during ejection. This style of gate is used to get the injection location behind or below a show surface. Banana gates often have the same limitations as submarine gates in terms of size.

Disk Gate: The feed is expanded along the outer circumference of the product. The injection point is symmetrical and the mold is evenly filled, which can eliminate the parting line and facilitate exhaust.

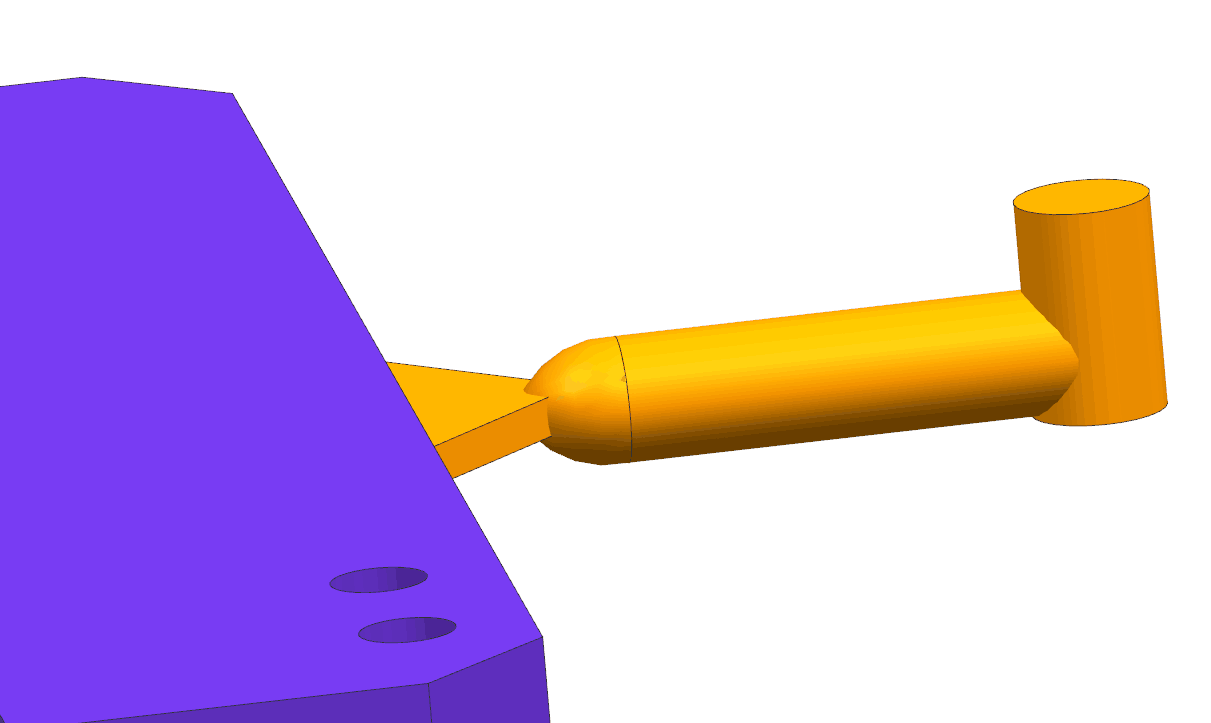

Fan Gate: From the runner to the cavity, it gradually enlarges into a fan shape. It is suitable for long or flat and thin products, which can reduce flow lines and directional stress.

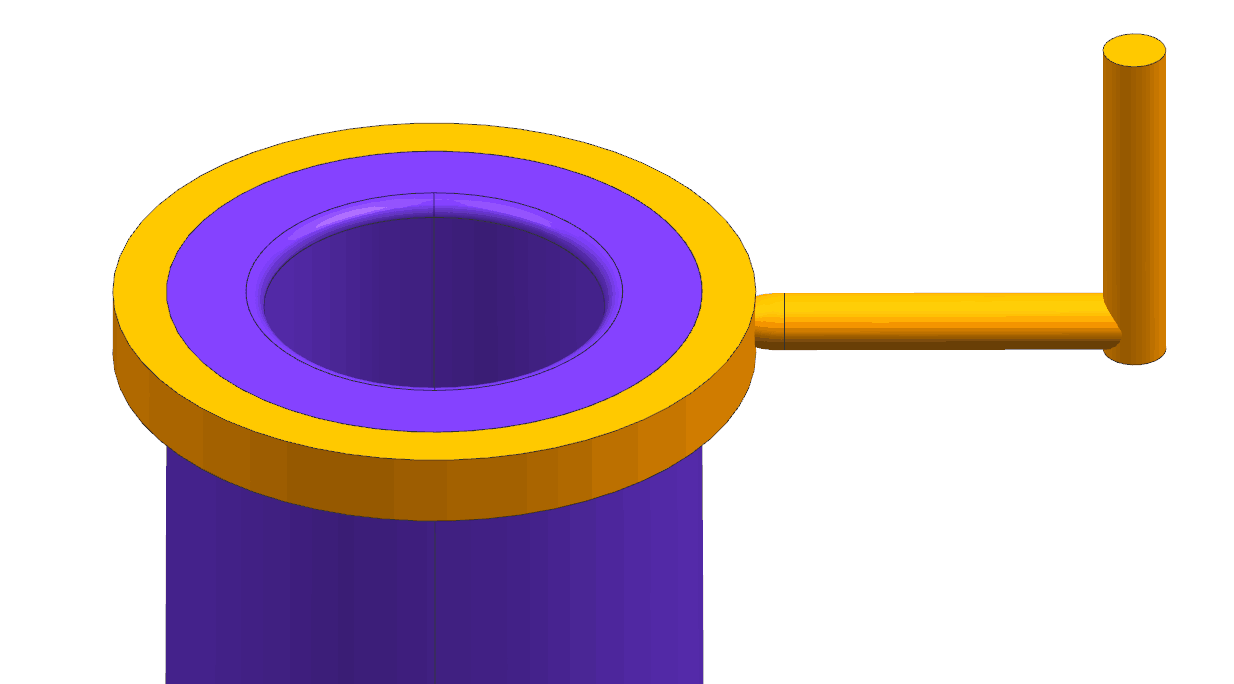

Ring Gate: It extends the plastic injection along the entire outer circumference of the product, which can make the plastic fill the mold uniformly around the core, have good exhaust, and reduce the parting line.

To sum up, choosing different gates depends on different product and mold requirements.

If you have any idea or questions about the gate designs, welcome to contact us sales@fitmold.com

Copyright © Fitmold, All right reserved.