Different Types of Gates for Injection Molding

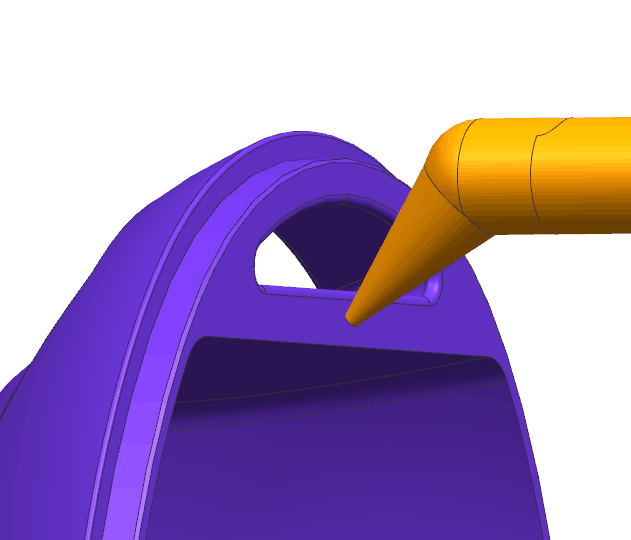

Different Types of Gates for Injection Molding Gate design plays an important role in plastic injection mold design. The location, size, and shape of a gate has a significant effect on a finished product whether from product structure or appearance.Fit Precision Mold Co.,Ltd summarize some types of gates, which is commonly used in injection molding. Pin-point Gate: It is a gate…