How CS Guns/Firearm are Made with Aluminum via CNC Machining?

Today we would like to share a case to make a plastic injection mold from a sample, which we believe could be of great value to your business, especially for some bosses are focus on automotive parts manufacturing, auto spare parts remanufacturing etc.

Background for the product in this case:

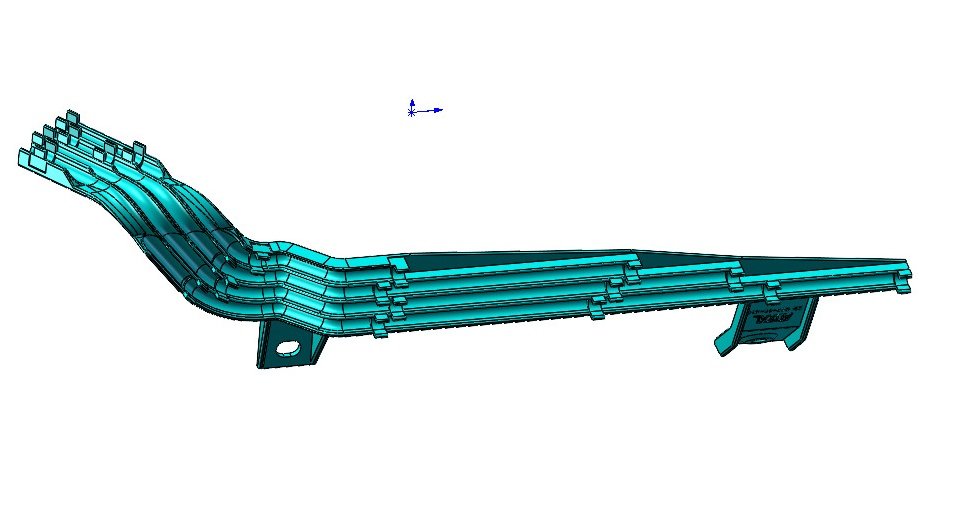

Sample from customer: Auto part, PA6+10GF material

3D model creating: Lead time: 7 days

Prototype material: UV Curable Resin

Prototype lead time: 3 days

Prototype delivery time: 5-7 days

Making a plastic injection mold from a sample can be a challenging process that requires careful planning and execution.

We need to do as following:

Obtain a sample of the product (From Clients): To create a mold from a sample, you need to have a physical sample of the product. This will help you understand the size, shape, and details of the product.

Create a 3D model: Once you have the sample, you can create a 3D model of the product using CAD software. This will help you create a design that matches the sample and meets your production requirements.

Prototype making: Once the 3D model created, you need to make a prototype to test product assembling and structure and verify 3D model’s accuracy.

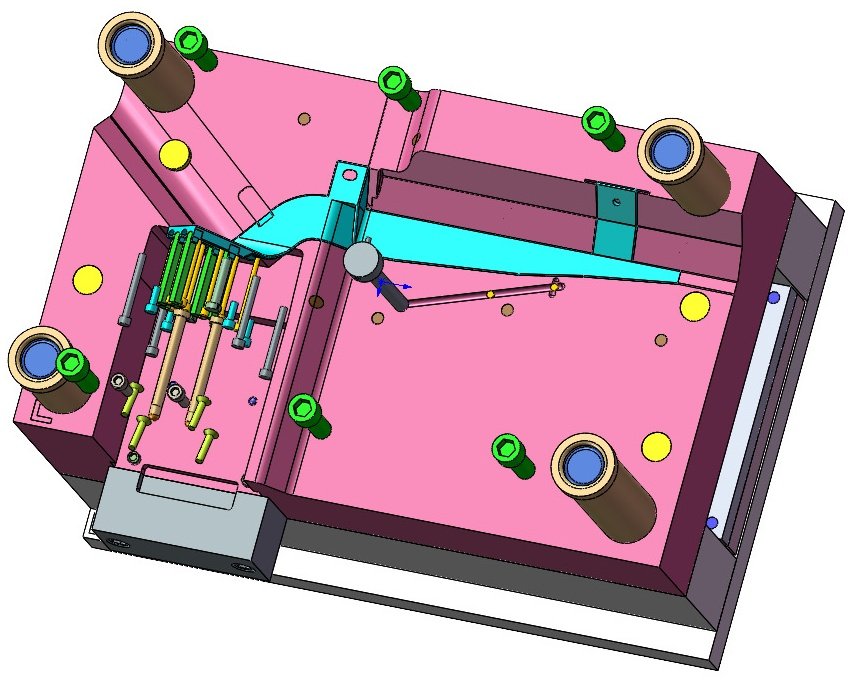

Design the mold and mold manufacturing: Using the 3D model, you can design the mold for the injection molding process. This will include the placement of the gate, runner, and ejector pins.

With the design complete, you can manufacturing the mold. This will involve machining the mold from a block of metal, such as aluminum or steel.

It’s important to note that making a mold from a sample can be a complex process that requires experience and expertise. Working with an experienced mold maker can help ensure that the mold is designed and built to meet your requirements.

As a experienced mold manufacturer, we would be delighted to share this case with you and to see if there is something we could assist your business. Please feel free to contact us if any question or inquires you have.