Working Flow

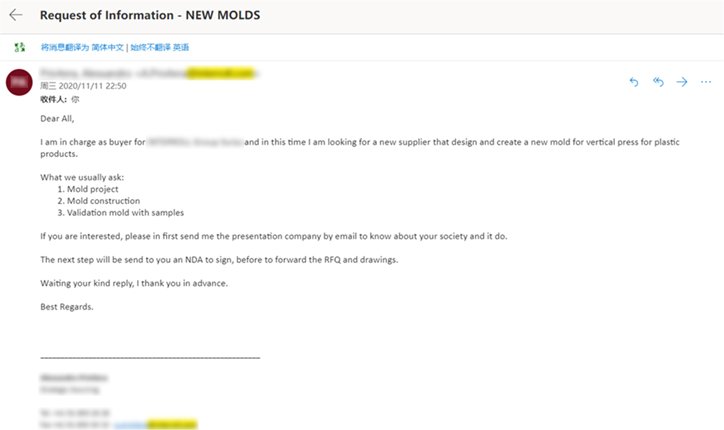

1.The customer sends us “RFQ”.

Typically the “RFQ” including the parts drawings which including 3D drawings (igs, stp, step, x_t format); 2D drawings (dxf, pdf blue printing contains the parameter of the parts); Other Supplementary requirements such as the material, color, surface finishing, etc. If you’re not a engineer, you can send us photos of your parts and other information of it. You can also send us sketching of your idea.

Typically the “RFQ” including the parts drawings which including 3D drawings (igs, stp, step, x_t format); 2D drawings (dxf, pdf blue printing contains the parameter of the parts); Other Supplementary requirements such as the material, color, surface finishing, etc. If you’re not a engineer, you can send us photos of your parts and other information of it. You can also send us sketching of your idea.

2.We will respond the “inquiry” once we received the data. Our following up will lead us to understanding of the project and enable to “quoting” right price. Communication is quite necessary, it helps us on understanding the project well enough, for example: part function, working environment, which surface is the most important. We will keep all the information secret. (NDA will be signed if its necessary)

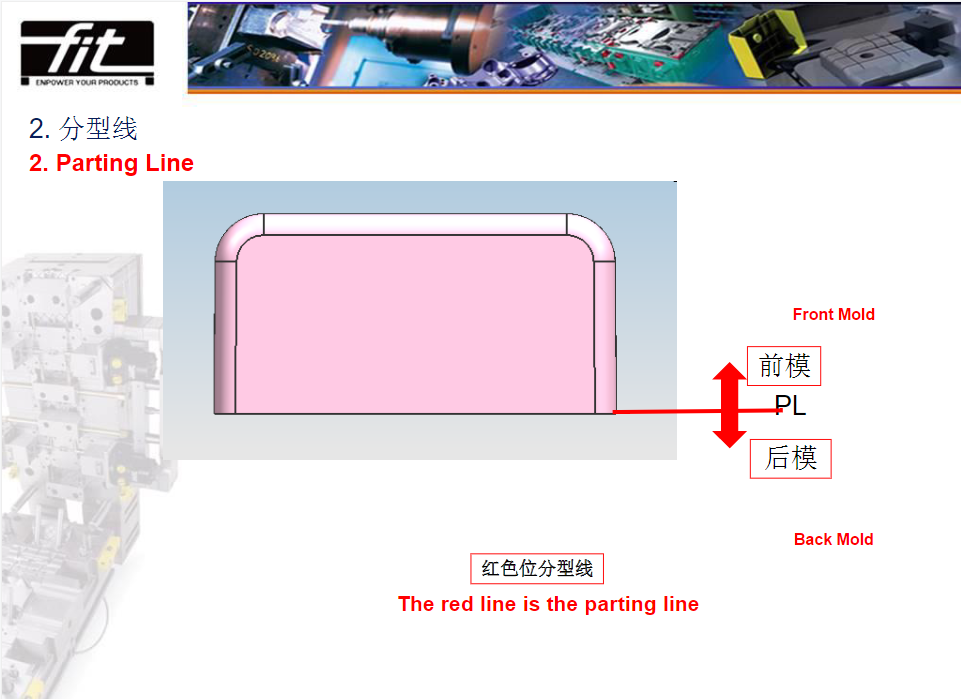

3.Before the tooling design, we will confirm with customer our idea of part making process. The engineering points covers how to make the tooling on the parting surface, drafting angle, gating points, the ejecting location, the heating, the venting and the cooling system.

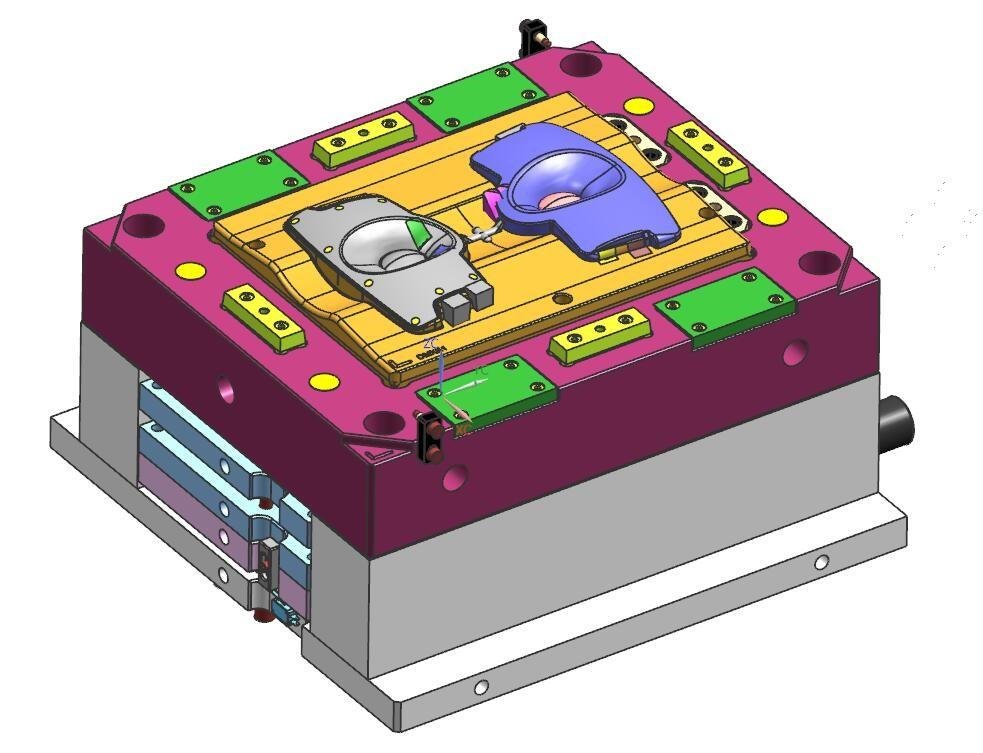

4.We will provide full design package which including 2D blue printing and 3D solid assembly drawings. The drawings will send to customers to check, once it’s approved we will get into next stage.

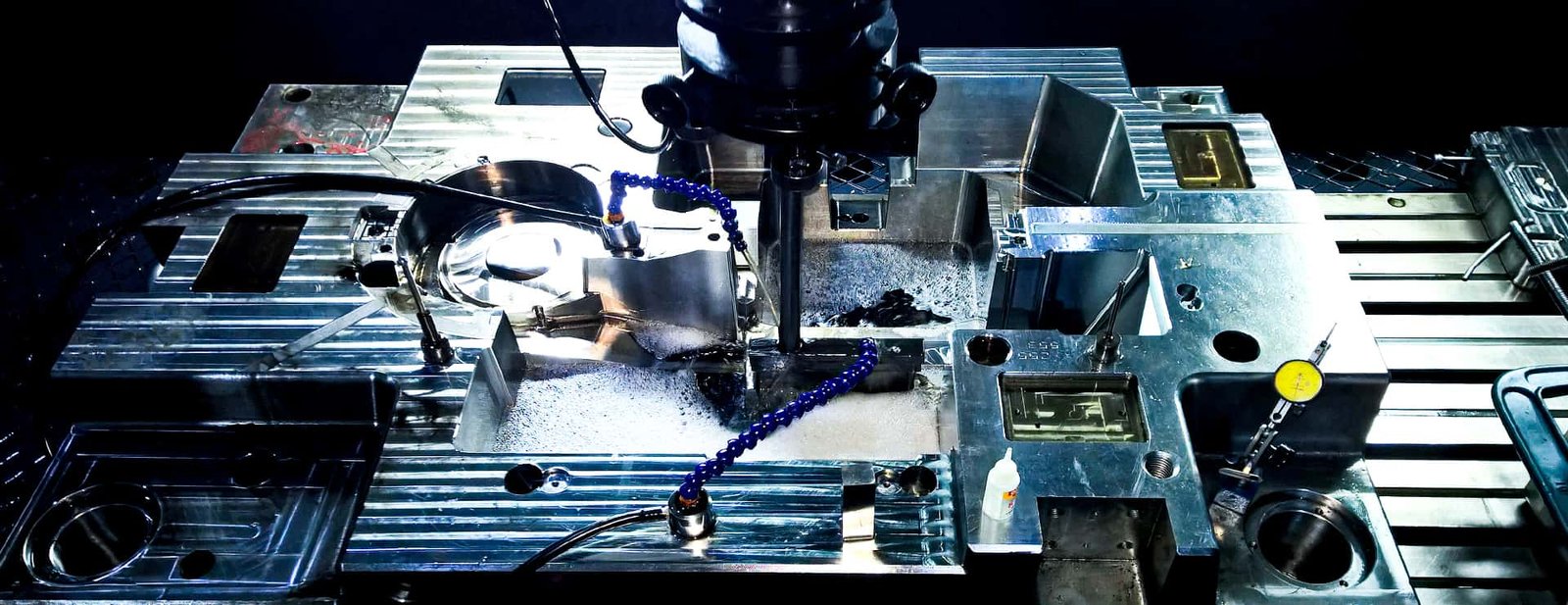

5.Tooling making is the most time-consuming work. In order to make customer keep abreast of real-time information. We will following up with our progress report with latest photos. Once the tooling is finished, it will be mounted onto injection machine to test. We will send the final testing samples to our customer. Once they approved the quality, the tooling making job is finished.

6.Before shipping we will take hours trail shooting to check the tooling performance. To protect the moisture, the tooling is wrapped by Protective film. Then it will be placed into Customized

wood box. We can quickly and efficiently deliver the goods to your hands by sea, air, express (DHL, UPS, FedEx, TNT) . We will negotiate with customers to choose the good shipping method.

wood box. We can quickly and efficiently deliver the goods to your hands by sea, air, express (DHL, UPS, FedEx, TNT) . We will negotiate with customers to choose the good shipping method.

7.FITMOLD can provide customers with injection molding, surface finishing, assembling, and further processing. These customers will Authorizing us to use the mold for production, and then transport the produced product to the customer’s designated location.

8.Normally we use sea shipping or train shipping for the big volume parts production.